1. Introduction

A rapidly expanding sector of the wind energy industry is floating wind energy devices. There are currently just three operational floating offshore wind farms that are connected to the grid: Hywind (30 MW) and Kincardine (50 MW) in Scotland, and Windfloat Atlantic (25 MW) near Viana de Castelo in Portugal [

1]. As of now, despite the rapid growth in this industry, the expenses associated with floating wind turbines are still much greater than those for fixed offshore ones.

The complexity and coupling of floating offshore wind turbine (FOWT) systems, as well as the presence of several excitation sources, make floating wind optimization challenging. As such, advanced modelling and design tools capable of precisely capturing these systems’ physical behaviour under realistic conditions are necessary. To this end, it is essential to understand and address the causes of inaccuracies and uncertainties in these tools in order to develop a cost-effective design tool for floating wind turbines. Currently, there are a number of different numerical and physical modelling methods available, both independently and with a cross-validation method [

1].

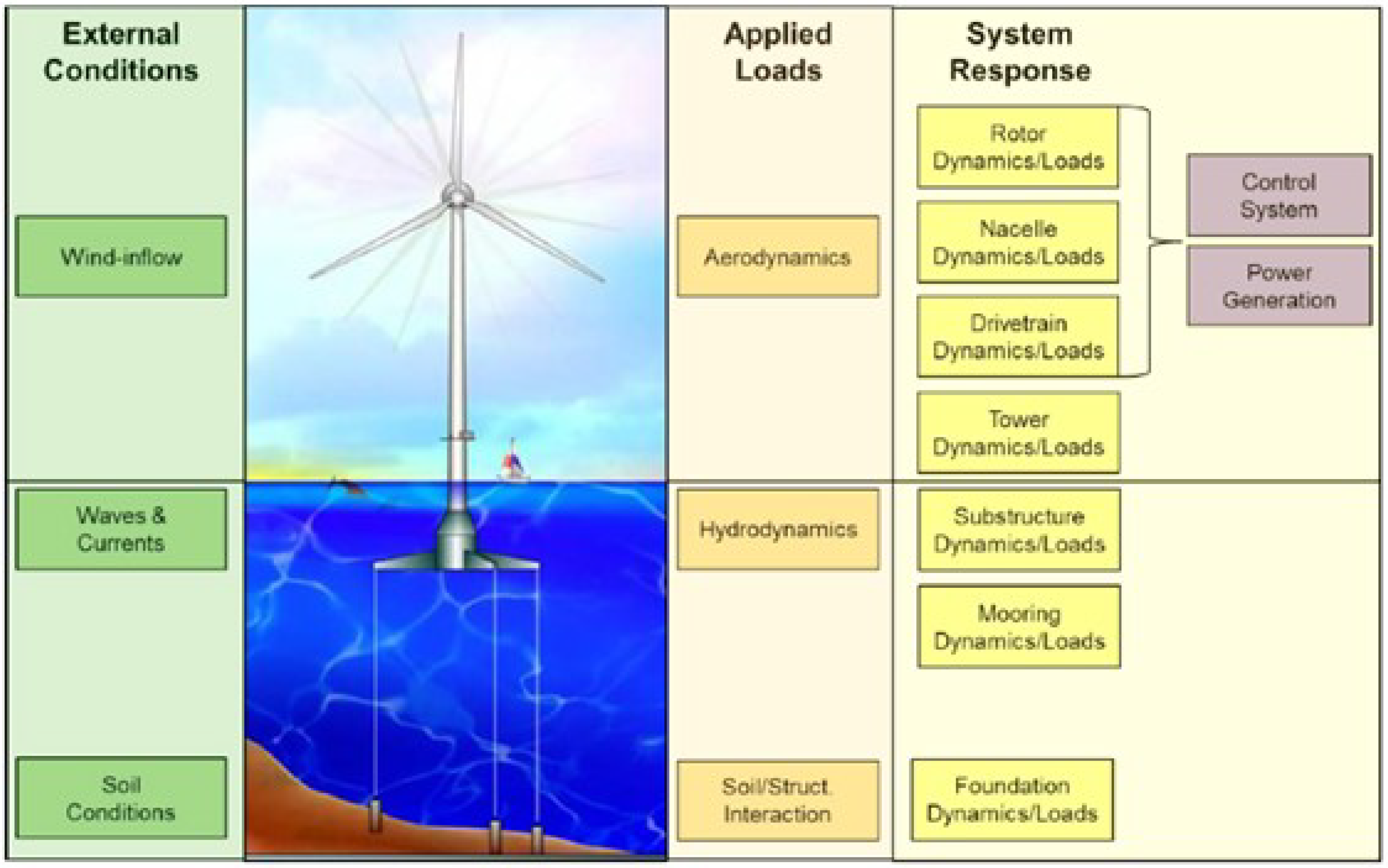

In recent years, a large variety of simulation tools have been developed to examine various structural dynamic, aerodynamic, wind-inflow, and control system models of wind turbines in the time-domain, as well as to anticipate and assess their response. Fields related to FOWTs have recently received substantial research attention because of the potential benefits of these systems over onshore systems. Waves, sea currents, hydrodynamics, and mooring systems have all been modelled to replicate the additional physical phenomena involved with offshore wind turbines. The various components of offshore wind turbine modelling tools are depicted in

Figure 1.

Figure 1.

Diagram of the components of offshore wind modelling tools [

2].

Figure 1.

Diagram of the components of offshore wind modelling tools [

2].

Almost all simulation codes for onshore and offshore wind turbines are based on time-domain solutions that use numerical techniques, like the Fast Fourier Transform (FFT), to simulate a wind turbine’s dynamic behaviour. Furthermore, the majority of these aeroelastic modelling codes are based on Blade Element Momentum (BEM) theory and Multibody Simulation (MBS) techniques, which allow for acceptable modification and prediction of rotor aerodynamics like tip loss correction, turbulent wake state, dynamic inflow, dynamic stall [

3,

4,

5,

6,

7].

In order to validate and verify the accuracy of the available simulation codes through code-to-code comparisons, two research tasks have been defined by the International Energy Agency (IEA) within Tasks 23 and 30 [

7,

8,

9]: The Offshore Code Comparison Collaboration (OC3) and the Offshore Code Comparison Collaboration, Continuation (OC4) projects. Subsequently, an extension of Task 30, the Offshore Code Comparison Collaboration Continuation and Correlation (OC5) was initiated in three different phases to address the limitation of the previous tasks by comparing the simulated response with physical response data from an experimental test, and identifying which solution is the most accurate [

10,

11,

12]. In 2019, the IEA Wind Task 30 defined the OC6 project (Offshore Code Comparison Collaboration, Continued, with Correlation, and Uncertainty) to improve the overall accuracy and predictive capability of the offshore wind turbine simulation codes [

13].

For numerical modelling of FOWT dynamic response, generally, four separate components of dynamic behaviour are considered: structural dynamics, hydrodynamics, aerodynamics, and control. This paper conducts a survey of numerical methods with the primary objective of evaluating and comparing various simulation tools for FOWTs. The key aim of this survey is to comprehensively cover the numerical simulation tools that have participated in the Offshore Code Comparison (OC) projects. These projects have played a crucial role in assessing the accuracy of the simulation tools through code-to-code and code-to-model comparisons, ensuring their reliability and effectiveness in FOWT analysis. Furthermore, the survey highlights the underlying theory, capabilities and limitations of these tools, shedding light on their suitability for different aspects of FOWT simulation.

2. FAST Computer-Aided Engineering Tool

FAST (Fatigue, Aerodynamics, Structures, and Turbulence) is the primary computer-aided engineering (CAE) tool applicable to wind turbines. It was developed by the National Renewable Energy Laboratory (NREL) with support from the United States Department of Energy. It simulates the coupled dynamic response of a variety of wind turbine configurations, including two- and three-bladed horizontal-axis rotors, pitch or stall regulation, rigid or teetering hubs, upwind or downwind rotors and lattice or tubular towers [

14,

15,

16].

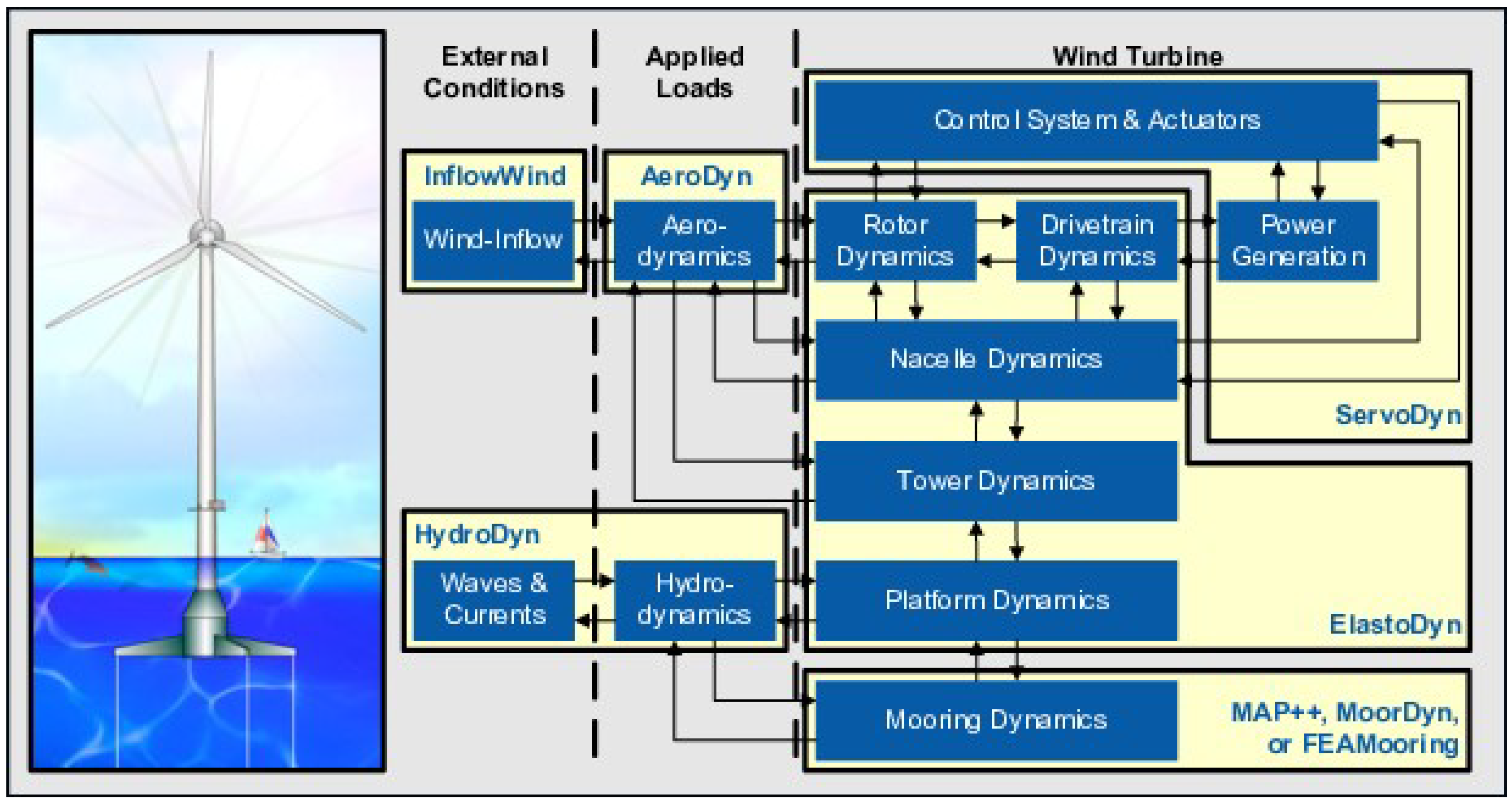

FAST includes a number of modules that use mathematical models to simulate one or more turbine components, such as AeroDyn (aerodynamics), HydroDyn (hydrodynamics of platform for offshore structures), ServoDyn (control and electrical systems), and BeamDyn or ElastoDyn (structural dynamics). The schematic of various modules available in FAST is depicted in

Figure 2. The time-domain simulation and investigation of coupled nonlinear aero-hydro-servo-elastic simulation of onshore or offshore wind turbines on the fixed-bottom or floating substructure is made possible by the assembly of these modules.

Figure 2.

FAST schematic [

15].

Figure 2.

FAST schematic [

15].

FAST was utilized as the principal simulation tool in the OC projects, and its numerical calculations for the OC3- Hywind and DeepCwind semisubmersible platforms were in good agreement with experimental results [

6,

11].

2.1. FAST Modularization Framework

NREL recently released the FAST Modularization Framework in order to improve the modularity of the FAST aero-hydro-servo-elastic simulation tool. As the core of this tool, FAST v8, is a software framework and algorithm for interconnecting modules in the time-domain [

17]. Modules can communicate in the FAST Modularization Framework using matching or non-matching spatial meshes with different time steps and time integrators. A predictor-corrector technique can be used to transfer data between modules, allowing for both implicit and explicit time integration within each module [

15,

17,

18,

19].

2.2. ElastoDyn

ElastoDyn is the main structural-dynamics module of FAST, where Kane’s method is used to construct and implement nonlinear equations of motion [

16,

20]. As a call-able module, it can be called in the framework with separate input files and source codes. ElastoDyn is based on a formulation that combines multibody dynamics (blade and tower) with modal-dynamics (platform, nacelle, generator, gears, and hub) [

19]. The dominant mode shapes in ElastoDyn are found externally through modal tests or BModes and are represented as 6th-order polynomials [

21].

ElastoDyn is based on Euler-Bernoulli beam theory in bending, meaning that no axial or torsional degrees of freedom (DOF) and no shear deformation are considered [

17,

22,

23,

24,

25]. As a result, the module is better suited to straight beams with isotropic material and no mass or elastic offsets, with small to moderate blade deflections, and some geometric nonlinearities[

17,

24,

25]. This module allows you to model any horizontal axis wind turbine (HAWT) with a 2- or 3-bladed, upwind or downwind rotor, with a rigid or teetering hub.

2.3. BeamDyn

NREL recently released BeamDyn, a new time-domain structural-dynamics module for modelling slender structures and advanced aeroelastically-tailored blades [

15,

17,

24,

25,

26]. For dynamic simulation of highly flexible composite wind turbine blades with bend-twist coupling, BeamDyn is integrated into the FAST modular framework [

17,

21,

24,

25]. BeamDyn substitutes in the place of ElastoDyn’s simplified blade structural model. BeamDyn is based on geometrically exact beam theory and is discretized in the space domain using the Legendre-spectral-finite-element (LSFE) [

17,

23,

24,

25]. This new module allows for the modelling of twisted composite blades with significant deformations, including bending, torsion, shear, and extensional DOFs [

17,

21,

23,

27]. It may also be used as a stand-alone high-fidelity beam tool.

2.4. AeroDyn

AeroDyn is used to perform the aerodynamic modelling for the FAST simulation tool. AeroDyn is a time-domain wind turbine aerodynamics module that may be used either independently to compute wind turbine aerodynamic response or in conjunction with FAST to enable aero-elastic modelling of wind turbines [

18]. AeroDyn solves for rotor-wake effects and blade-element aerodynamic loads, including dynamic stall, using wind-inflow data [

18]. Rotor Wake/Induction, Blade Airfoil Aerodynamics, Tower Influence on the Blade Nodes, and Tower Drag are the four submodules of AeroDyn [

28,

29]. The BEM theory and the generalized dynamic-wake (GDW) theory are two models in AeroDyn for calculating the effect of wind turbine wakes. Many wind turbine designers employ BEM theory, whereas GDW theory is a more contemporary development that can be used to simulate skewed and unsteady wake dynamics [

18,

29,

30]. AeroDyn v15.04 is a new NREL release that includes improvements to skewed-wake, dynamic wake, and unsteady airfoil aerodynamics modelling, as well as the ability to model highly flexible and curved or swept blades [

18,

28,

29,

30,

31].

2.5. HydroDyn

The time-domain hydrodynamics module of the NREL simulation tool known as HydroDyn has been integrated with FAST, to enable aero-hydro-servo-elastic simulation of offshore wind turbines. This module, however, can also be used to compute hydrodynamic loads as a stand-alone module. HydroDyn supports both fixed-bottom and floating offshore installations. In HydroDyn, the hydrodynamic loads on a structure are calculated using a potential-flow theory solution (radiation/diffraction), a strip-theory solution (via an extension of Morison equation), or a combination of the two (radiation/diffraction and the drag component of Morison equation) [

16,

19,

24,

30,

32].

Linear hydrostatic restoring; nonlinear viscous drag from incident-wave kinematics, sea currents, and platform motion; added-mass and damping contributions from linear wave radiation, including free-surface memory effects; and incident-wave excitation from linear diffraction in regular or irregular seas are all features that HydroDyn can account for [

16,

33].

2.6. InflowWind

For processing wind-inflow data, a new module named InflowWind was created, which can also be used independently of FAST. Undisturbed wind inflow such as steady, uniform, and time-varying deterministic like gusts; full-field (FF) turbulence models like TurbSim and Mann; and a specific user-defined format are among the wind formats supported by the InflowWind module [

34,

35].

2.7. SubDyn

NREL developed SubDyn, a time-domain structural-dynamics module for multi-member fixed-support substructures . It can also be used as a standalone code to compute the mode shapes, natural frequencies, and time-domain free vibration response of substructures independently from the rest of the wind turbine system. SubDyn can support a variety of substructure types, including monopiles, tripods, jackets, and other lattice-type substructures widely used for offshore wind turbine installations, as well as lattice support structures for land-based wind turbines [

36,

37].

2.8. MAP++

MAP++ is designed as a library for modelling the steady-state forces on a multi-segmented quasi-static (MSQS) mooring line in conjunction with other CAE tools. The MSQS module in MAP++ solves all algebraic equations for all elements with a resultant of zero at connection points at the same time. Modelling of seabed contact, seabed friction, and externally applied forces are also included in MAP++ [

38,

39,

40,

41].

2.9. MoorDyn

MoorDyn is a lumped-mass modelling technique that was created in 2015. Its purpose is to use Morison equation to capture key phenomena linked to FOWT mooring systems, such as mooring stiffness, inertia and damping forces in the axial direction, weight and buoyancy effects, seabed contact forces, and hydrodynamic loads from mooring motion. The MoorDyn module does not take into account bending and torsional cable stiffness, as well as bottom friction [

42,

43,

44].

2.10. FEAMooring

FEAMooring is a finite element based mooring-dynamics module that, while integrated into FAST, may also be used to compute mooring dynamics as an independent code. Different types of mooring systems, such as catenary mooring, taut mooring, and tendons, can be analyzed using FEAMooring. It calculates mooring-line reaction forces at the floating platform’s fairlead positions while taking into consideration mooring dynamics including inertia and drag forces at each line element [

41,

45,

46,

47].

2.11. IceFloe and IceDyn

IceFloe (Quasi Steady Ice Loading) and IceDyn (Ice Dynamics) are two modules created by NREL to model ice floe loading on vertical and sloping structures when bottom-fixed offshore wind turbines interact with surface ice [

48,

49,

50].

2.12. Transition to OpenFAST

The NREL recently created the OpenFAST (previously known as FAST) to model the physical phenomena and dynamic response of the entire wind turbine system (rotor, tower, support structure, nacelle, drivetrain, and controller) to normal and extreme environmental loading conditions (wind, wave, and current). OpenFAST was released to help with the transition to an open-source community-based development of FAST as an aero-hydro-servo-elastic simulation tool, as well as to provide a framework for future development of FAST with features such as automated regression and unit tests, source code documentation, and a compiler built system [

15,

51].

3. OrcaFlex

OrcaFlex is a time-domain, finite-element commercial software for dynamic analysis of marine systems developed by Orcina [

52]. It is notable for its dynamic mooring line representation and comprehensive hydrodynamic modelling capability [

53,

54], which allows it to model a multi-member floating support system as discrete elements. Moreover, OrcaFlex is capable of performing a fully-coupled analysis of both onshore and offshore wind turbines [

52,

53]. The long-established hydrodynamic capabilities of OrcaFlex are combined with a built-in aerodynamic turbine model by embedding it into OpenFAST, resulting in a fully-coupled dynamic analysis tool applicable for both fixed and floating platform offshore wind turbines. Nonetheless, in FAST v8 there is a module called OrcaFlexInterface that computes all hydrodynamic and mooring loads, while FAST computes the turbine, tower, and floating platform structural dynamics, aerodynamics, and control and electrical-drive dynamics [

55].

OrcaFlex supports both frequency-domain and time-domain dynamic analysis. The frequency-domain analysis is a linear procedure. The frequency-domain solver approximates any nonlinearities through the process of linearization. The nonlinearity of time-domain analysis is more comprehensive since at each time step, mass, damping, stiffness, loading, and other parameters are evaluated, taking into consideration the instantaneous, time-varying geometry. OrcaFlex uses a 3-D finite element model to simulate mooring-line dynamics. To model the axial, torsional, and bending stiffness and damping of lines, they are discretized as lumped mass elements connected to visco-elastic spring-damper segments. Moreover, the two types of time-domain integration schemes, implicit and explicit, have been implemented in OrcaFlex and are available to user [

56].

The blade modelling is similar to OrcaFlex line objects where each blade is modelled as of a series of straight massless segments with a node at each end [

56].

4. OPASS

Offshore Platform Anchorage System Simulator (OPASS), developed by the Spanish National Renewable Energy Center (CENER), is a tool for simulating nonlinear mooring dynamics using a lumped mass model [

57,

58]. OPASS is built using the finite-element method, with three translational DOF at each node and element mass lumped at nodes. Each element is made up of a slender line with a constant circular section, with the effects of inertia, gravity, hydrodynamic added mass, hydrostatic, wave kinematics, hydrodynamic drag, structural damping, and axial elasticity all taken into account [

57]. The code can be used as a standalone tool to simulate mooring lines, or it can be used with FAST to model mooring lines using a quasi-static technique [

57,

59].

The collaboration between CENER and Norway’s Institute for Energy Technology (IFE) has resulted in various scaled experiments for experimental validation and verification of OPASS. OPASS was initially validated using 3DFloat code computations [

60], a dynamic mooring line module based on a finite element formulation [

57,

61]. Following that, OPASS was combined with FAST V6.02, and the final tool was satisfactorily confirmed as an aero-hydro-servo elastic simulation code under IEA task 30’s OC4 project [

2,

57]. Furthermore, OPASS was experimentally confirmed in a tank test at the Ecole Centrale de Nantes (ECN) against a submerged chain. OPASS was recently verified against test data from a submerged chain in which the suspension point was excited with horizontal harmonic motions of various periods in the plane of the catenary [

57,

58]. By considering the mooring lines as dynamic systems, Azcona et al. combined OPASS and FAST to compute the fatigue and ultimate loads of three distinct platform concepts of FOWTs (The UMaine TLP [

62], the OC4 DeepCwind semisubmersible [

63], and the UMaine Hywind spar [

7]).

5. Bladed

Bladed is an integrated aero-hydro-servo-elastic modelling package developed by Det Norske Veritas (Norway) and Germanischer Lloyd (Germany) (DNV GL) which is capable of modelling both onshore and offshore wind turbines. Bottom-fixed offshore structures, such as jackets, can be designed in Bladed with beam components and flexible joints, or imported from third-party offshore design tools like SESAM and SACS [

64]. Bladed can also simulate FOWTs using a mooring line system. Bladed models the dynamics of the mooring line as a multibody system in which bar components are linked together with universal joints to form a chain [

64].

Bladed uses a flexible multibody dynamics technique in its structural dynamics code. Various flexible and rigid bodies can be linked together to model the entire system in this method. The Craig-Bampton approach is used to calculate the mode shapes and frequencies for each flexible body as a linear finite element body [

64,

65,

66,

67]. Each blade splits into several flexible bodies to form a geometrically-nonlinear model capable of large deflections, whereas the tower is modelled using modal analysis [

64,

66,

67]. This approach is a key feature of Bladed that allows stability analysis and determining the dynamic response of large modern wind turbine blades. Bladed’s multibody dynamics framework is also used to describe other physical components of wind turbines, such as pitch drives and generators [

64].

Morison equation provides the basis for the Bladed’s hydrodynamic module. Since Morison equation cannot be applied adequately for structures with large members, wave diffraction and radiation terms can be important, and the boundary element approach can be utilized to calculate hydrodynamic loads [

2]. Furthermore, Bladed can be linked to a third-party hydrodynamic code like WAMIT, AQWA, or WADAM, and then hydrodynamic properties imported into Bladed [

64].

Bladed uses BEM theory to implement aerodynamic loads, and it can accommodate sophisticated unsteady aerodynamics by using the following models [

64,

67]:

Prandtl’s tip and root loss, to account for the effect of the blade tip vortices on induced velocity;

Dynamic wake model;

Glauert skew model; and

Dynamic stall model, including Beddoes-Leishman compressible and incompressible flows and Øye dynamic stall.

Bladed can generate a variety of wind models, including steady and dynamic models, as well as turbulent wind files. It can also provide earthquake acceleration time histories for turbines in seismic zones, which can be used to determine the effects on turbine loads [

64].

6. HAWC2

The coupled aeroelastic Horizontal Axis Wind Turbine Simulation Code 2nd Generation (HAWC2) was created at Risoe National Laboratory in Denmark between 2003 and 2006 as part of an aeroelastic design research program [

68]. The code has been tested both internally against the previous version, HAWC, and empirically against other offshore simulation codes used in OC research projects under IEA Annex 23 and Annex 30 [

2,

6,

7,

9,

10,

11,

12,

13,

68,

69]. The HAWCStab2 is another software tool created by Technical University of Denmark (DTU) Wind Energy for computing and analyzing the modal parameters of a wind turbine in both closed and open-loop operations with or without unsteady aerodynamic loads [

70].

HAWC2 is a time-domain tool for analysis of wind turbine dynamic response. Each body is an assembly of Timoshenko beam elements, and the structural module is formulated using a multibody dynamics technique. Modelling and analysis of complicated structures with large deflections and rotations of the bodies are possible with this formulation method. HAWC2 simulates a wind turbine by connecting bodies with constraint equations, with a constraint being a fixed connection to a global point (e.g. tower bottom clamping), a fixed coupling of relative motions (e.g. fixed pitch or yaw), frictionless bearings, and bearings with user-controlled rotation angles [

68,

71].

The aerodynamic loads are estimated using the conventional BEM approach, which has been extended to account for dynamic stall, skew inflow, dynamic inflow, and shear effects on the induction factor, as well as the effects of modern wind turbine blade deflection. In addition, the new Dynamic Wake Meandering (DWM) model has been included in HAWC2 [

70], which is capable of capturing the response of turbines running in the wake of upstream turbines.

In HAWC2, the hydrodynamic load is estimated using Morison equation. However, wave kinematics are not calculated. Externally-defined Dynamic Link Library (DLL) interfaces are used, which contain regular and irregular Airy waves [

68]. The wind turbine’s control is planned to be accomplished by coupling one or more external controllers via DLL interfaces [

68].

7. aNySIM

aNySIM is an in-house time-domain hydrodynamic code developed by the Netherlands’ Maritime Research Institute (MARIN) in 2006. The goal of aNySIM is to simulate the coupled behavior of floating structures, taking into consideration wave, current, and wind loadings, as well as floating body dynamics and mooring dynamics [

72].

Offshore oil and gas facilities including one or more vessels in offloading operations, mooring simulations and multibody lifting operations, and dynamic positioning capability investigations are some of the traditional applications of aNySIM [

73,

74,

75]. However, aNySIM has recently been utilized to simulate floating wind turbines [

76].

The hydrodynamic loads in aNySIM are calculated using potential flow theory, and the potential damping and added-mass of floating bodies are converted into a non-frequency-dependent added mass in the time-domain [

72,

77].

8. PHATAS

Energy Research Centre of the Netherlands (ECN) developed the computer Program for Horizontal Axis Wind Turbine Analysis and Simulation (PHATAS) tool to determine loads on horizontal axis wind turbines and model their dynamic response in the time-domain. PHATAS is part of the wind turbine design package FOCUS which was developed by the Wind turbine, Materials and Constructions (WMC) in Technology Center Netherlands (TCN) [

78,

79].

In PHATAS, a significant number of structural DOF can be represented [

79]:

Continuous flapwise blade bending

Continuous edgewise blade bending

Passive or controlled pitch

Blade flapping hinges

Teetered hub

Generator characteristics

Drive train

Tower torsion

Tower bending

The flexibility of the wind turbine blades is calculated using a nonlinear deflection model while following the Craig-Bampton method and a modal approach is used for modelling the tower [

80].

The aerodynamic rotor loads in PHATAS are determined based on the BEM theory with the assumption of a stationary (equilibrium) wake. Moreover, the flow around the blade tips is described using the tip loss factor of Prandtl [

79].

9. 3DFloat

3DFloat is a fully coupled algorithm created by the Wind Energy Department at IFE and is frequently used to simulate the dynamic response of floating wind turbines during the conceptual design stage [

81].

IEA has evaluated 3DFloat against various codes as part of OC initiatives. It has also been used to model the OC3-Hywind floating wind turbine for the OC3 project [

7], the bottom-fixed (with jacket type) wind turbine for the OC4 project [

8], and the semisubmersible platform for the OC4 project [

2]. It has also been tested in wave tanks for three different types of tension-leg buoys [

82], a semisubmersible platform [

83], and the OC5 project [

10].

3DFloat is based on a nonlinear co-rotational FEM framework that takes into account geometric nonlinearities and connects computational nodes with elements. Each element is modelled as a 12-DOF Euler-Bernoulli beam. In addition, each element has structural, aerodynamic, and hydrodynamic characteristics in relation to the principal axes of the section and the axial direction. The calculation is done in the time-domain using either implicit methods such as the generalized

method and the Newmark scheme, or explicit methods such as the central difference scheme [

84].

Wind, waves, gravity, and buoyancy are all applied as distributed external loads on the structure in 3DFloat. Regular wave kinematics can be defined using either Airy theory or stream functions up to order 12 [

60,

85]. Morison equation is used to compute wave and current loads on the wet part of the structure and for slender beams [

60]. Furthermore, a third-party module such as WAMIT [

86], NEMOH [

87], or WADAM [

88] can be utilized to compute the frequency-dependent added mass and damping coefficient matrices for a given structural element.

BEM theory is used to determine the aerodynamic loads and induced velocity over the rotors with modification for dynamic inflow and yaw errors. The turbulence model is imported from HAWC or TURBSIM turbulence files [

60].

For wind speeds below the rated wind speed, the control system in 3DFloat is designed for a variable speed rotor with constant blade pitch angle. For wind speeds greater than the rated wind speed, proportional integral (PI) control of pitch angle is utilised to control the rotor’s speed and power. The control module of 3DFloat includes a Dynamic Link Library interface [

60].

10. DeepLines Wind

DeepLines Wind is a comprehensive software developed jointly by Principia and IFP Energies Nouvelles [

89] for the dynamic response of fixed-bottom and FOWTs subjected to ultimate and fatigue offshore environmental loadings. Constant winds, unsteady wind gusts, conventional wind spectra, and full field turbulent wind are all represented as environmental loads in DeepLines Wind using Airy and nonlinear wave theories; user defined or random wave spectra like JONSWAP; and steady and unsteady current profiles [

89,

90,

91].

The structural dynamics of the blades are characterized using 3D beam dynamic finite elements that account for the structural twist, variable stiffness, structural damping along the blade, as well as in-plane and out-of-plane pre-bends [

89,

90,

91].

The rotor’s aerodynamic loads are computed using BEM theory, which includes improvements for dynamic stall and tower shadow effects [

89,

90,

91].

The hydrodynamic loads are calculated using drag and inertia Morison elements, diffraction and radiation loads, first-order wave loads (based on potential flow), and second-order wave loads (based on Newman or Quadratic Transfer Function (QTF)). Nonlinear hydrostatic loads can alternatively be represented by pressure integrals across the hull surface or by bar elements [

89,

90,

91,

92].

The mooring system for floating wind turbines can be modelled either as a solid subjected to hydrodynamic loads using potential flow theory or as deformable assembled elements subjected to hydrodynamic loads using Morison equations [

89,

90,

91].

11. SAMCEF

turbine concept. CAESAM, SAMCEF Field, and SAMCEF Mecano [

93,

94,

95] are among the SAMTECH general tools used by S4WT. CAESAM is a general framework for integrating models and computational tools to perform transient, modal, and fatigue analysis of wind turbines. SAMCEF is a graphical pre-processor tool that helps S4WT build wind turbine components. Finally, SAMCEF Mecano is SAMCEF’s implicit nonlinear finite element solver [

93,

94], which contains multibody simulation elements.

In S4WT, the structural formulation is based on geometrically exact nonlinear beam theory, and the blades are modelled using a nonlinear FEM approach that is suitable for nonlinear modelling and composite blades subjected to large deformation. Furthermore, the blade model can be expressed as super elements or nonlinear beam elements [

94,

95].

The aerodynamic loads are computed using BEM theory with various corrections and additional models to account for tip and hub losses, the tower shadow effect, dynamic inflow, and dynamic stall. S4WT may import wind loads from external software such as Bladed or Flex 5, or build them using its built-in models [

95,

96]. To account for structural and hydrodynamic coupling effects, the hydrodynamic formulation is implemented in SAMCEF Mecano and uses the Morison equation [

96].

12. Sesam

Sesam has been in use since 1969 for hydrodynamic and structural analysis of offshore structures. The key tools in Sesam, including GeniE, Sima, HydroD, and DeepC, are utilized for modelling and simulation programs as entry points for various sectors [

97,

98,

99].

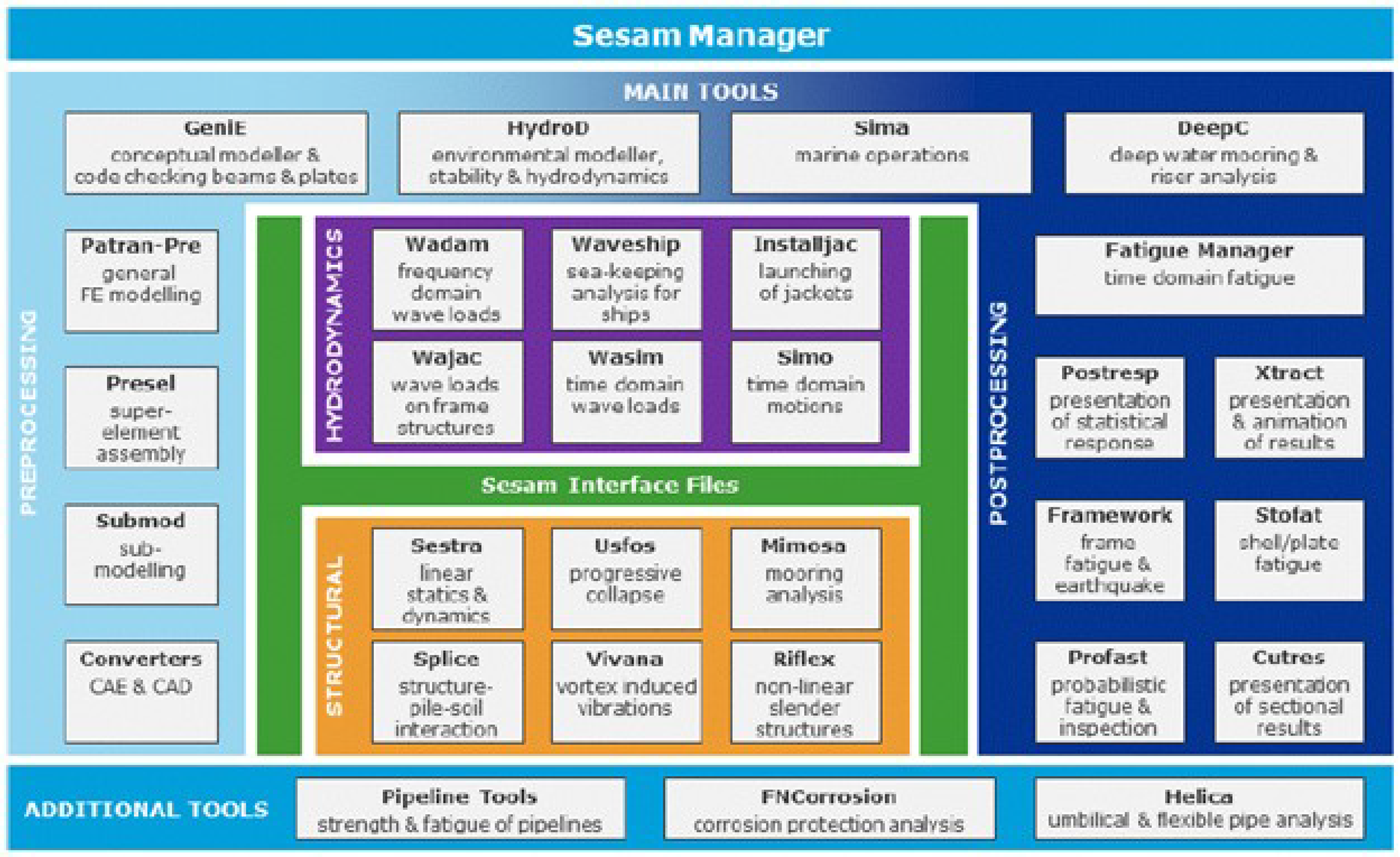

The preprocessor, hydrodynamic analysis programs, structural analysis programs, and postprocessors are the four programs that make up Sesam [

97]. An overview of Sesam is presented in

Figure 3.

Figure 3.

Sesam overview [

97].

Figure 3.

Sesam overview [

97].

GeniE is the Sesam entry point for designing and evaluating fixed offshore structures as well as offshore wind turbine platforms. It is defined for conceptual modelling of beams, stiffened plates and shells, as well as code validation. The following packages are available as a result of combining analytic programs with GeniE [

97,

98,

99]:

- −

Sestra: A program for static and dynamic structural analysis. The finite element approach was used to formulate it. Sestra may also analyze gap/contact problems and members that are just in tension or compression.

- −

Wajac: Wind, wave, and current loads on fixed and rigid frame structures are calculated using this program. In either a frequency- or time-domain simulation, the load is calculated using the Morison equation. The hydrodynamic loads due to irregular, regular, or constrained waves can be computed using time-domain analysis.

- −

Splice: Nonlinear analysis of the structure-pile-soil interaction problems.

- −

Framework: Fatigue analysis of structures.

- −

Fatigue Manager: Time-domain fatigue and ultimate strength analysis under combined wind and wave loads.

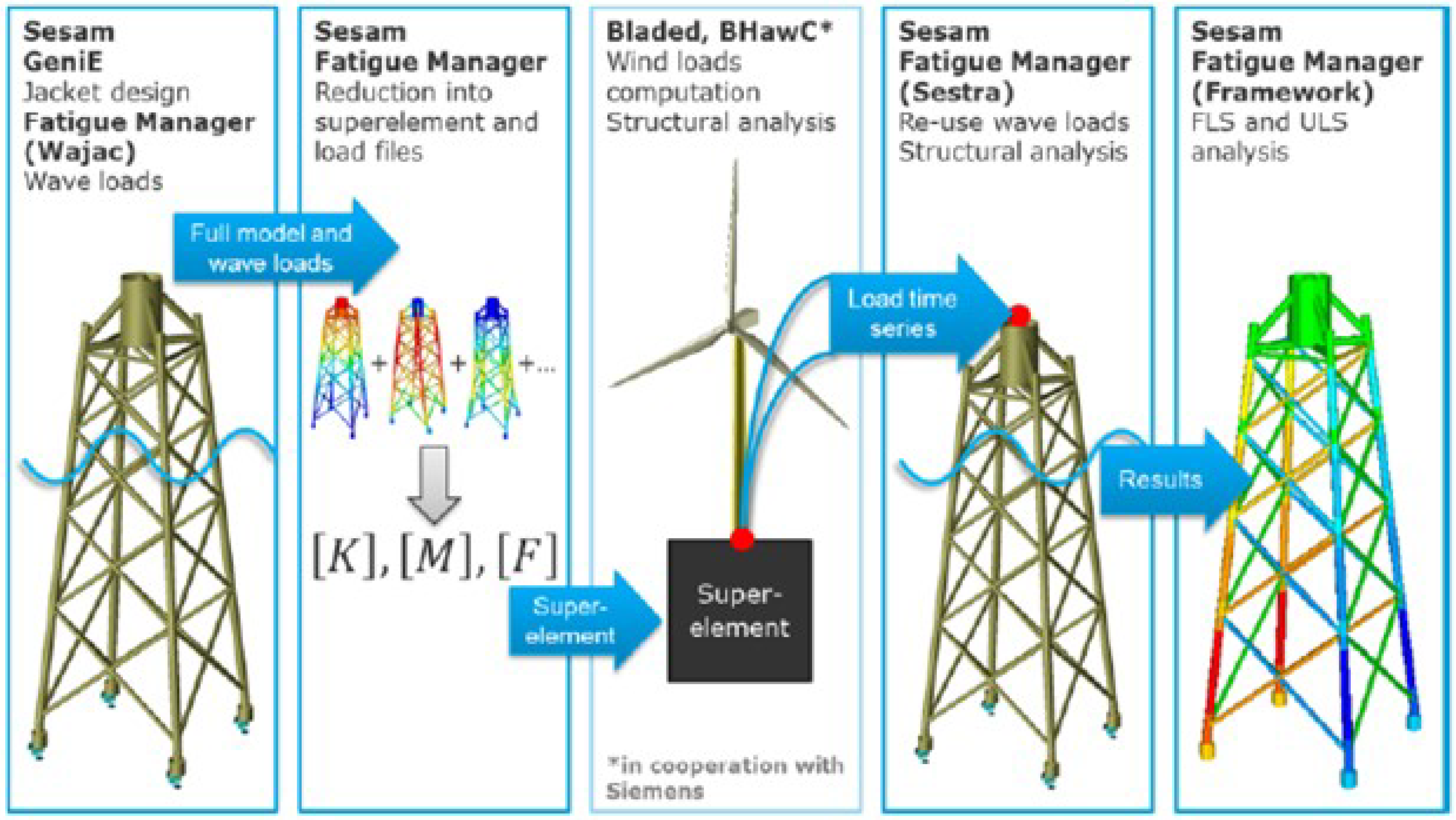

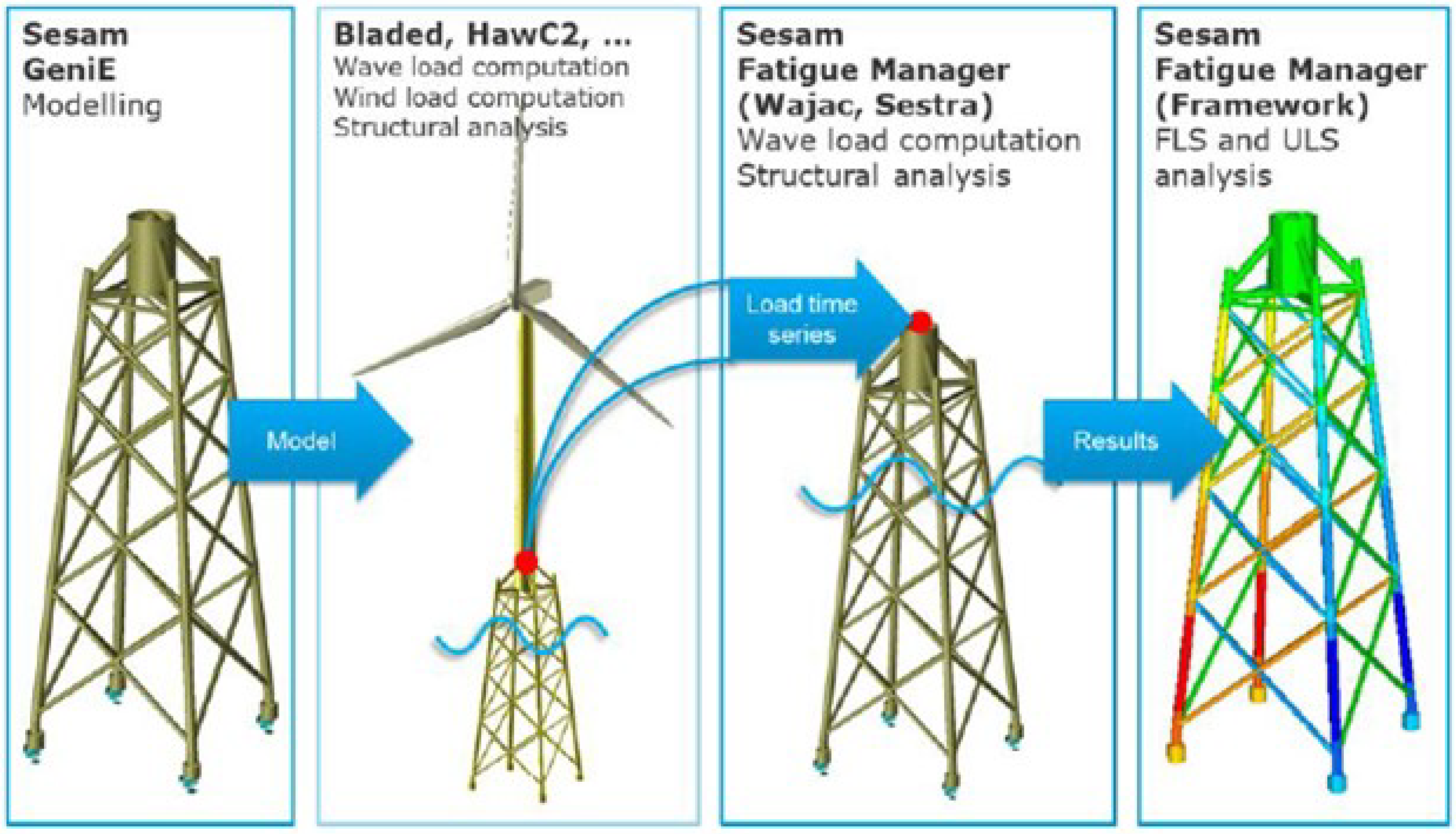

In reference to the schematic depicted in

Figure 3, the entry points to the package for floating structures are HydroD (modelling and stability analysis module) and GeniE for the following applications [

97,

98,

100]:

- −

-

Wadam: Linear frequency-domain hydrodynamics.

The hydrodynamic loads are determined using the Morison equation as well as first- and second-order potential theory. In addition, through frequency-domain simulation analysis, the incident waves are defined as an Airy wave.

- −

-

Wasim: Nonlinear time-domain hydrodynamic.

Wasim is based on the Morison equation, which uses the Rankin panel approach to solve the 3D diffraction/radiation problem.

- −

-

Sima: Modelling, analysis, control, and results presentation.

It is a time-domain simulation tool that uses a fully-coupled technique to simulate a floating wind turbine. The hydrodynamics of the substructure can be estimated using conventional hydrodynamic programs, while the mooring system can be specified in Sima.

- −

Simo: Simulation of motions.

- −

Riflex: Analysis of moorings.

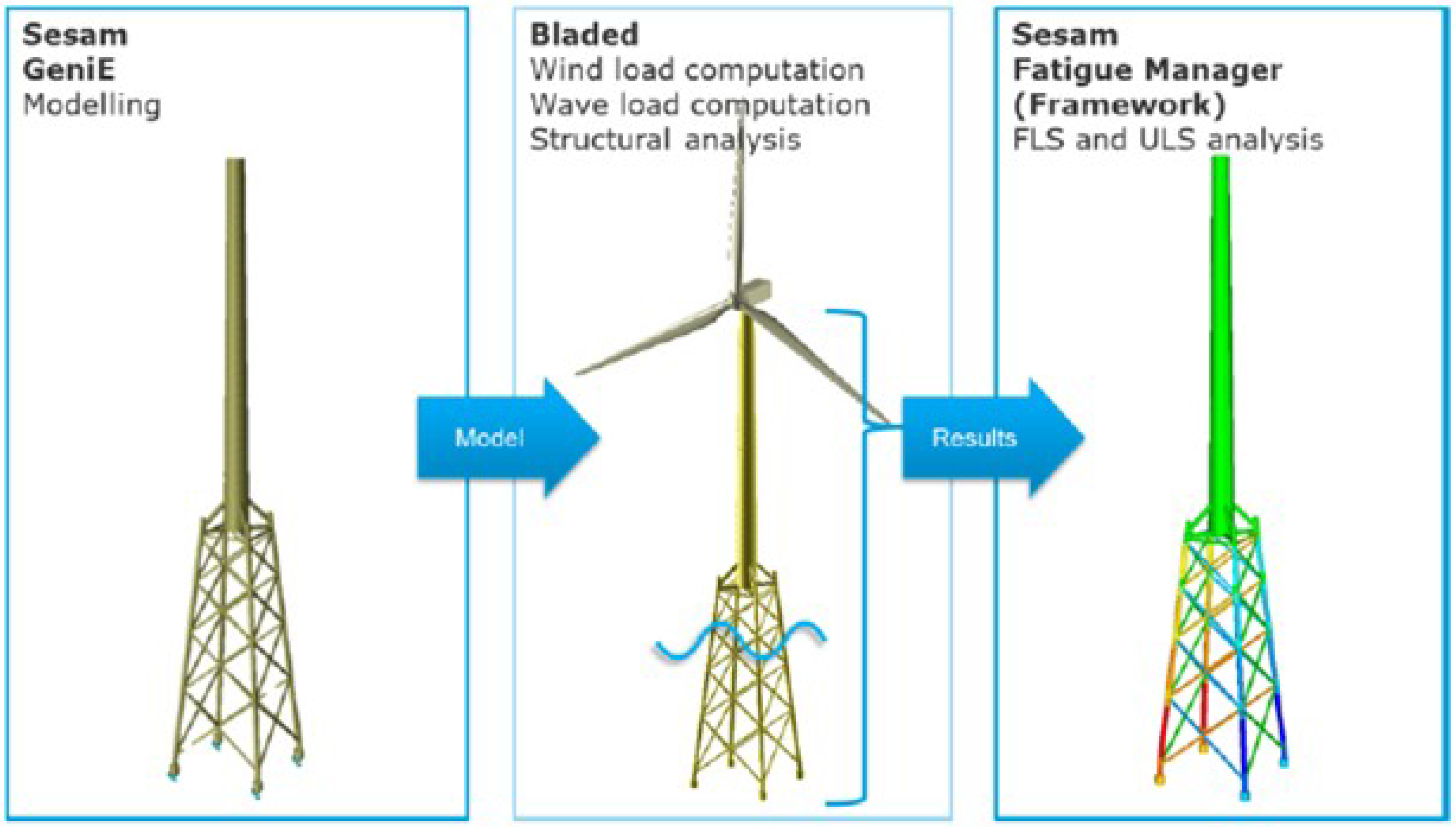

Three methods of analysis are available in the Sesam software [

98]:

Integrated analysis: This method involves modelling in Sesam, which is then imported and coupled to a wind turbine model in a tool like Bladed. After computing the resulting forces and loads for each component, the data is translated into Sesam for post-processing, which includes fatigue and ultimate analysis, as shown in

Figure 4.

Figure 4.

Overview of the integrated approach concept with the help of Sesam package and Bladed [

98].

Figure 4.

Overview of the integrated approach concept with the help of Sesam package and Bladed [

98].

Super-element and Sequential analysis : Wave loads are generated in Sesam using the super-element technique. The wind turbine is modelled in a separate third-party software package, and the wind turbine loads are extracted at an interface point. Sesam may use wind turbine loads from any third-party wind turbine tool, where converters for Bladed, BHAWC, and HAWC2 are available. These loads are then incorporated into the Sesam analysis, followed by a dynamic analysis to determine the structure’s stress time histories. Following that, the stresses are post-processed to meet fatigue limit state and/or ultimate limit state criteria [

98]. A super-element approach is employed in a special type of sequential analysis, in which the model and wave loads are converted into a super-element file and wave load files from Sesam, which are then used by the turbine load calculation tool. This is mostly used in conjunction with Bladed and Siemens Gamesa’s BHAWC. These approaches are illustrated in

Figure 5 and

Figure 6.

Figure 5.

Overview of the super-element approach concept with the aid of the Sesam package, Bladed, and HAWC2 [

98].

Figure 5.

Overview of the super-element approach concept with the aid of the Sesam package, Bladed, and HAWC2 [

98].

Figure 6.

Overview of the sequential approach concept with the aid of the Sesam package and Bladed [

98].

Figure 6.

Overview of the sequential approach concept with the aid of the Sesam package and Bladed [

98].

13. UTWind

UTWind is a rotor-floater-mooring coupled analysis code established by the University of Tokyo for a variety of floater platforms used in FOWTs [

101,

102,

103,

104]. In a weak coupling algorithm, the coupled motions of the rotor-floater-mooring system are addressed in the time-domain using the Newmark beta time integration approach.

The beam elements are utilized to model the blades and floaters as a frame structure, while the lumped mass model is used to represent the mooring system. The rotor motion is defined in a fixed rotating coordinate system with Coriolis and centrifugal forces taken into account.

The aerodynamic loads are estimated using the BEM approach, which accounts for tip and hub loss as well as changes in air inflow velocity due to floater motion [

101,

102]. The Hooft’s method [

105] has been used in the code for computing the hydrodynamic loads [

101,

102,

103,

104]. However, for the cylindrical structure elements, the modified Morison equation is utilized for hydrodynamic loads calculation [

101].

14. Discussion

For the design process of a FOWT prototype as an earlier stage, a variety of numerical approaches and software programs are available. A novel design is often produced as a numerical model, which is subsequently tested in a lab setting at model scales. Designers of FOWT technology may, however, be trying to employ high-fidelity numerical tools in an effort to lessen reliance on expensive and time-consuming physical testing as well as reduce the uncertainty of simpler numerical models. Lower fidelity models, on the other hand, might be important when taking into account lifetime operations, maintenance issues, and control. In general, accuracy and fidelity as well as computational effectiveness at an acceptable performance level in the phenomena of interest are the major significant factors that differentiate one numerical modelling approach from another. Here, accuracy is defined as the difference between predicted values and observed physical responses. However, fidelity reflects how much the underlying physics or phenomena of interest have been simplified by the numerical model, giving a level of assurance that the accuracy predicted during simulations is indeed attained. On the other hand, the time it takes for a simulation to finish using normal computer hardware is a common way to assess computational efficiency [

1].

Overall, numerical models may be divided into three categories: low-fidelity, mid-fidelity, and high-fidelity. As fidelity increases, larger computational resources are demanded thus leading to a reduction in computational efficiency. For sizing analysis and optimization at the first stage of FOWT design, low-fidelity models are typically employed. In order to analyze loads on FOWTs under operational and extreme scenarios, following the original design stage, mid-fidelity models, or engineering-level tools, are utilized. In the last stages of design, high-fidelity models are frequently utilized for thorough studies, particularly to precisely determine stresses on the structure.

Table 1 gives a thorough summary of the underlying numerical methods for the main FOWT modules for the engineering tools presented in this study.

Table 1.

Summary of reviewed numerical simulation tools capabilities used to model a FOWT.

Table 1.

Summary of reviewed numerical simulation tools capabilities used to model a FOWT.

| Software |

Structure |

Aerodynamic |

Hydrodynamic |

Mooring |

Analysis Type |

| OpenFAST |

RB + Modal/FEM + Dyn/QS |

BEM + GDW/FVW |

PF + ME |

Lumped-mass + MSQS or with FEAMooring |

time-domain |

| OrcaFlex |

RB + FEM + Dyn |

With OpenFAST |

PF + ME |

3-D FEM |

both |

| OPASS |

With OpenFAST |

With OpenFAST |

With OpenFAST |

Lumped-mass |

time-domain [106] |

| Bladed |

Modal |

BEM + GDW |

ME + third-party code like WAMIT or coupled with SESAM |

MBD |

time-domain [106] |

| HAWC2 |

FEM + Dyn |

BEM + GDW |

ME + external DLL or third-party code like WAMIT |

Shared mooring line design [107] or with SIMO/RIFLEX [108] |

time-domain |

| aNySIM |

with PHATAS [109] |

with PHATAS [109] |

PF |

Lumped-mass lines [110] |

time-domain |

| PHATAS |

FEM + Modal |

BEM |

with aNySIM [109] |

with aNySIM [109] |

time-domain |

| 3DFloat |

FEM |

BEM |

ME + third-party code like WAMIT |

FEM [57] |

time-domain |

| DeepLines Wind |

FEM |

BEM |

ME + PF + QTF |

Solid elements + PF or deformable elements + ME |

time-domain |

| SAMCEF |

FEM + MBD |

BEM |

ME |

FEM + ME [111] |

time-domain |

| Sesam |

FEM |

With Bladed/HAWC2 |

ME + PF + Airy wave |

Panel method + ME [108] |

both |

| UTWind |

BE |

BEM |

Hooft’s method + ME |

Lumped-mass [104] |

time-domain |

15. Conclusion

In conclusion, this survey provides a comprehensive evaluation and comparison of numerical tools for simulating FOWTs. The available simulation tools include both commercial software initially used in the oil and gas industry and in-house academic codes. In this regard, several commercial and in-house academic codes have proven to be reliable and effective for modelling a floating wind turbine, such as OrcaFlex or OpenFAST, which have also been evaluated and compared in experimental studies through OC projects. In the available numerical tools, computational effectiveness and fidelity are typically the two main characteristics that set these simulation tools apart from one another. Computing efficiency is a criterion that assesses a simulation tool’s capacity to perform a simulation using common computing resources in a reasonable amount of time. However, due to the relative inadequacy of the numerical models, computational efficiency may be viewed as a low-percentage of outputs deviating from the experimental scaled test results. Correspondingly, fidelity—which is regarded as the correctness of the physics or phenomena behind the numerical techniques—is another factor that is important in selecting the appropriate simulation tool.

Moreover, the two primary analytical approaches that have been employed in simulation tools are frequency- and time-domain simulation types. Time-domain techniques are employed in the last stages of design, as well as to assess global dynamic analysis and optimization phases, whereas frequency-domain approaches are mostly used in the early stages of design and for sizing FOWTs. In this context, time-domain models are among the mid- to high-fidelity simulation tools, whereas frequency-domain techniques are low-fidelity approaches.

Overall, code-to-code and code-to-model comparisons, uncertainty analyses, and correlation projects have demonstrated that, despite the proliferation of cutting-edge simulation tools for FOWTs, at this juncture, most numerical engineering tools still require accuracy improvements, especially for hydrodynamic loads at low frequencies and motion response in the surge and pitch direction of FOWTs.

Author Contributions

Conceptualization, Saeid Fadaei; Methodology, Saeid Fadaei; Resources, Saeid Fadaei; Data Curation, Saeid Fadaei; Writing—original draft preparation, Saeid Fadaei; Writing—review and editing, Saeid Fadaei. Fred F. Afagh. Robert G. Langlois; Visualization, Saeid Fadaei; Supervision, Fred F. Afagh. Robert G. Langlois; Project Administration, Fred F. Afagh. Robert G. Langlois. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results”.

References

- Otter, A.; Murphy, J.; Pakrashi, V.; Robertson, A.; Desmond, C. A review of modelling techniques for floating offshore wind turbines. Wind Energy 2022, 25, 831–857. [Google Scholar] [CrossRef]

- Robertson, A.; Jonkman, J.; Vorpahl, F.; Popko, W.; Qvist, J.; Frøyd, L.; Chen, X.; Azcona, J.; Uzunoglu, E.; Soares, C.G.; Luan, C.; Yutong, H.; Pengcheng, F.; Yde, A.; Larsen, T.; Nichols, J.; Buils, R.; Lei, L.; Nygaard, T.A.; Manolas, D.; Heege, A.; Vatne, S.R.; Ormberg, H.; Duarte, T.; Godreau, C.; Hansen, H.F.; Nielsen, A.W.; Riber, H.; Le Cunff, C.; Beyer, F.; Yamaguchi, A.; Jung, K.J.; Shin, H.; Shi, W.; Park, H.; Alves, M.; Guérinel, M. Offshore code comparison collaboration continuation within IEA wind task 30: Phase II results regarding a floating semisubmersible wind system. Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering - OMAE 2014, 9B. [Google Scholar] [CrossRef]

- Sayed, M.; Klein, L.; Lutz, T.; Krämer, E. The impact of the aerodynamic model fidelity on the aeroelastic response of a multi-megawatt wind turbine. Renewable Energy 2019, 140, 304–318. [Google Scholar] [CrossRef]

- Riziotis, V.A.; Voutsinas, S.G.; Politis, E.S.; Chaviaropoulos, P. K. Hansen, A.M.; Madsen Aagaard, H. Rasmussen, F. Identification of structural non-linearities due to large deflections on a 5MW wind turbine blade. Scientific proceedings; European Wind Energy Conference and Exhibition: Brussels, 2008; pp. 9–14.

- Jeong, M.S.; Yoo, S.J.; Lee, I. Aeroelastic Analysis for Large Wind Turbine Rotor Blades. 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference; American Institute of Aeronautics and Astronautics: Reston, Virigina, 2011. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Kolios, A. State of the art in the aeroelasticity of wind turbine blades: Aeroelastic modelling. Renewable and Sustainable Energy Reviews 2016, 64, 195–210. [Google Scholar] [CrossRef]

- Jonkman, J.M.; Musial, W. Offshore Code Comparison Collaboration (OC3) for IEA Wind Task 23 Offshore Wind Technology and Deployment. Technical report, National Renewable Energy Laboratory, USA, 2010.

- Popko, W.; Vorpahl, F.; Zuga, A.; Kohlmeier, M.; Jonkman, J.; Robertson, A.; Larsen, T.J.; Yde, A.; Sætertrø, K.; Okstad, K.M.; Nichols, J.; Nygaard, T.A.; Gao, Z.; Manolas, D.; Kim, K.; Yu, Q.; Shi, W.; Park, H.; Vásquez-Rojas, A.; Dubois, J.; Kaufer, D.; Thomassen, P.; de Ruiter, M.J.; van der Zee, T.; Peeringa, J.M.; Zhiwen, H.; von Waaden, H. Offshore code comparison collaboration continuation (OC4), Phase I-results of coupled simulations of an offshore wind turbine with jacket support structure. Journal of Ocean and Wind Energy 2014, 1, 1–11. [Google Scholar] [CrossRef]

- Robertson, A.; Jonkman, J.M.; Musial, W.; Vorphal, F.; Popko, W. Offshore Code Comparison Collaboration, Continuation: Phase II Results of a Floating Semisubmersible Wind System. roceedings, EWEA Offshore;, 2013.

- Robertson, A.N.; Wendt, F.F.; Jonkman, J.M.; Popko, W.; Vorpahl, F.; Stansberg, C.T.; Bachynski, E.E.; Bayati, I.; Beyer, F.; de Vaal, J.B.; Harries, R.; Yamaguchi, A.; Shin, H.; Kim, B.; van der Zee, T.; Bozonnet, P.; Aguilo, B.; Bergua, R.; Qvist, J.; Qijun, W.; Chen, X.; Guerinel, M.; Tu, Y.; Yutong, H.; Li, R.; Bouy, L. OC5 Project Phase I: Validation of Hydrodynamic Loading on a Fixed Cylinder, 2015.

- Robertson, A.N.; Wendt, F.; Jonkman, J.M.; Popko, W.; Dagher, H.; Gueydon, S.; Qvist, J.; Vittori, F.; Azcona, J.; Uzunoglu, E.; Soares, C.G.; Harries, R.; Yde, A.; Galinos, C.; Hermans, K.; de Vaal, J.B.; Bozonnet, P.; Bouy, L.; Bayati, I.; Bergua, R.; Galvan, J.; Mendikoa, I.; Sanchez, C.B.; Shin, H.; Oh, S.; Molins, C.; Debruyne, Y. OC5 Project Phase II: Validation of Global Loads of the DeepCwind Floating Semisubmersible Wind Turbine. Energy Procedia 2017, 137, 38–57. [Google Scholar] [CrossRef]

- Robertson, A.N.; Wendt, F.; Jonkman, J.M.; Popko, W.; Borg, M.; Bredmose, H.; Schlutter, F.; Qvist, J.; Bergua, R.; Harries, R.; Yde, A.; Nygaard, T.A.; de Vaal, J.B.; Oggiano, L.; Bozonnet, P.; Bouy, L.; Sanchez, C.B.; García, R.G.; Bachynski, E.E.; Tu, Y.; Bayati, I.; Borisade, F.; Shin, H.; van der Zee, T.; Guerinel, M. OC5 Project Phase Ib: Validation of Hydrodynamic Loading on a Fixed, Flexible Cylinder for Offshore Wind Applications. Energy Procedia 2016, 94, 82–101. [Google Scholar] [CrossRef]

- Robertson, A.N.; Gueydon, S.; Bachynski, E.; Wang, L.; Jonkman, J.; Alarcón, D.; Amet, E.; Beardsell, A.; Bonnet, P.; Boudet, B.; Brun, C.; Chen, Z.; Féron, M.; Forbush, D.; Galinos, C.; Galvan, J.; Gilbert, P.; Gómez, J.; Harnois, V.; Haudin, F.; Hu, Z.; Dreff, J.L.; Leimeister, M.; Lemmer, F.; Li, H.; Mckinnon, G.; Mendikoa, I.; Moghtadaei, A.; Netzband, S.; Oh, S.; Pegalajar-Jurado, A.; Nguyen, M.Q.; Ruehl, K.; Schünemann, P.; Shi, W.; Shin, H.; Si, Y.; Surmont, F.; Trubat, P.; Qwist, J.; Wohlfahrt-Laymann, S. OC6 Phase I: Investigating the underprediction of low-frequency hydrodynamic loads and responses of a floating wind turbine. Journal of Physics: Conference Series 2020, 1618, 032033. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development. Technical report, National Renewable Energy Laboratory (NREL), Golden, CO, 2009. [CrossRef]

- Jonkman, J.M.; Wright, A.D.; Hayman, G.J.; Robertson, A.N. Full-System Linearization for Floating Offshore Wind Turbines in OpenFAST. ASME 2018 1st International Offshore Wind Technical Conference. American Society of Mechanical Engineers, 2018. [CrossRef]

- Jonkman, J.M. Dynamics of offshore floating wind turbines-model development and verification. Wind Energy 2009, 12, 459–492. [Google Scholar] [CrossRef]

- Wang, Q.; Sprague, M.A.; Jonkman, J.; Johnson, N.; Jonkman, B. BeamDyn: a high-fidelity wind turbine blade solver in the FAST modular framework. Wind Energy 2017, 20, 1439–1462. [Google Scholar] [CrossRef]

- Ning, A.; Hayman, G.; Damiani, R.; Jonkman, J.M. Development and Validation of a New Blade Element Momentum Skewed-Wake Model within AeroDyn. 33rd Wind Energy Symposium; American Institute of Aeronautics and Astronautics: Reston, Virginia, 2015. [Google Scholar] [CrossRef]

- Wendt, F.F.; Robertson, A.; Jonkman, J.M.; Hayman, G. Verification of New Floating Capabilities in FAST v8. 33rd Wind Energy Symposium; American Institute of Aeronautics and Astronautics: Reston, Virginia, 2015. [Google Scholar] [CrossRef]

- Branlard, E.S.P. Flexible multibody dynamics using joint coordinates and the Rayleigh-Ritz approximation: The general framework behind and beyond Flex. Wind Energy 2019, 22, 877–893. [Google Scholar] [CrossRef]

- Saverin, J.; Peukert, J.; Marten, D.; Pechlivanoglou, G.; Paschereit, C.O.; Greenblatt, D. Aeroelastic simulation of multi-MW wind turbines using a free vortex model coupled to a geometrically exact beam model. Journal of Physics: Conference Series 2016, 753, 082015. [Google Scholar] [CrossRef]

- Dose, B.; Rahimi, H.; Stoevesandt, B.; Peinke, J.; Schepers, J. On the effect of blade deformations on the aerodynamic performance of wind turbine rotors subjected to yawed inflow. Journal of Physics: Conference Series 2018, 1037, 022030. [Google Scholar] [CrossRef]

- Qu, X.; Li, Y.; Tang, Y.; Chai, W.; Gao, Z. Comparative study of short-term extreme responses and fatigue damages of a floating wind turbine using two different blade models. Applied Ocean Research 2020, 97, 102088. [Google Scholar] [CrossRef]

- Wang, Q.; Sprague, M.A.; Jonkman, J.M. Nonlinear Legendre Spectral Finite Elements for Wind Turbine Blade Dynamics. 32nd ASME Wind Energy Symposium; American Institute of Aeronautics and Astronautics: Reston, Virginia, 2014. [Google Scholar] [CrossRef]

- Wang, Q.; Sprague, M.A.; Jonkman, J.M. Partitioned nonlinear structural analysis of wind turbines using BeamDyn. 34th Wind Energy Symposium; American Institute of Aeronautics and Astronautics: Reston, Virginia, 2016. [Google Scholar] [CrossRef]

- Jonkman, J.M.; Jonkman, B.J. FAST modularization framework for wind turbine simulation: full-system linearization. Journal of Physics: Conference Series 2016, 753, 082010. [Google Scholar] [CrossRef]

- Wang, Q.; Jonkman, J.M.; Sprague, M.; Jonkman, B. BeamDyn User’s Guide and Theory Manual. Technical report, National Renewable Energy Laboratory, 2016.

- Damiani, R.R.; Hayman, G. The Unsteady Aerodynamics Module For FAST8. Technical report, National Renewable Energy Laboratory (NREL), Golden, CO (United States), 2019. [CrossRef]

- Karimirad, M.; Bachynski, E.E. Sensitivity Analysis of Limited Actuation for Real-time Hybrid Model Testing of 5MW Bottom-fixed Offshore Wind Turbine. Energy Procedia 2017, 137, 14–25. [Google Scholar] [CrossRef]

- Yang, Y.; Bashir, M.; Michailides, C.; Li, C.; Wang, J. Development and application of an aero-hydro-servo-elastic coupling framework for analysis of floating offshore wind turbines. Renewable Energy 2020, 161, 606–625. [Google Scholar] [CrossRef]

- Yang, Y.; Bashir, M.; Wang, J.; Yu, J.; Li, C. Performance evaluation of an integrated floating energy system based on coupled analysis. Energy Conversion and Management 2020, 223, 113308. [Google Scholar] [CrossRef]

- Benitz, M.A.; Schmidt, D.P.; Lackner, M.A.; Stewart, G.M.; Jonkman, J.; Robertson, A. Validation of Hydrodynamic Load Models Using CFD for the OC4-DeepCwind Semisubmersible. Volume 9: Ocean Renewable Energy. American Society of Mechanical Engineers, 2015. [CrossRef]

- Matha, D. Model Development and Loads Analysis of an Offshore Wind Turbine on a Tension Leg Platform with a Comparison to Other Floating Turbine Concepts: 09. Technical report, National Renewable Energy Laboratory (NREL), Golden, CO (United States), 2010. 20 April. [CrossRef]

- Guntur, S.; Jonkman, J.; Schreck, S. ; Jonkman, Bonnie, Wang, Q.; Sprague, M.; Hind, M.; Sievers, R. FAST v8 Verification and Validation for a Megawatt-Scale Wind Turbine with Aeroelastically Tailored Blades: Preprint. American Institute of Aeronautics and Astronautics Science and Technology Forum and Exposition (SciTech 2016);, 2016.

- Jonkman, B.J. Turbsim User’s Guide: Version 1.50. Technical report, National Renewable Energy Laboratory (NREL), Golden, CO (United States), 2009. [CrossRef]

- Damiani, R.; Jonkman, J.; Hayman, G. SubDyn User’s Guide and Theory Manual. Technical report, National Renewable Energy Laboratory (NREL), Golden, CO (United States), 2015. [CrossRef]

- Song, H.; Damiani, R.; Robertson, A.N.; Jonkman, J.M. New Structural-Dynamics Module for Offshore Multimember Substructures within the Wind Turbine Computer-Aided Engineering Tool FAST: Preprint. 23rd International Ocean, Offshore and Polar Engineering Conference ISOPE 2013;, 2013.

- Andersen, M.T.; Wendt, F.F.; Robertson, A.; Jonkman, J.; Hall, M. Verification and Validation of Multisegmented Mooring Capabilities in FAST v8. Twenty-sixth (2016) International Ocean and Polar Engineering Conference (ISOPE);, 2016.

- Masciola, M.D.; Jonkman, J.M.; Robertson, A. Implementation of a Multisegmented, Quasi-Static Cable Model. Twenty-Third (2013) International Offshore and Polar Engineering Conferenc;, 2013.

- Masciola, M.D. MAP++ Documentation, 2017.

- Wendt, F.; Robertson, A.; Jonkman, J.; Andersen, M.T. Verification and Validation of the New Dynamic Mooring Modules Available in FAST v8: Preprint. Twenty-sixth (2016) International Ocean and Polar Engineering Conference (ISOPE);, 2016.

- Hall, M. Efficient Modelling of Seabed Friction and Multi-Floater Mooring Systems in MoorDyn. Proceedings of the 12th European Wave and Tidal Energy Conference;, 2017.

- Pribadi.; Donatini.; Lataire. Numerical Modelling of a Mussel Line System by Means of Lumped-Mass Approach. Journal of Marine Science and Engineering 2019, 7, 309. [CrossRef]

- Hall, M. MoorDyn User’s Guide. Technical report, University of Maine, 2015.

- Bae, Y. Development of a dynamic mooring module feam for fast v8. Technical report, Texas A and M University, TX, USA, 2014.

- Min, H. Numerical Simulation of Floating Offshore Wind Turbine Dynamic Responses with Experimental Comparison. Doctoral dissertation, Texas A and M University, 2018.

- Andersen, M.T. Floating Foundations for Offshore Wind Turbines. PhD thesis, Aalborg University, 2016. [CrossRef]

- Yu, B.; Karr, D.G.; Song, H.; Sirnivas, S. A Surface Ice Module for Wind Turbine Dynamic Response Simulation Using FAST. Journal of Offshore Mechanics and Arctic Engineering 2016, 138. [Google Scholar] [CrossRef]

- Karr, D.G.; Yu, B.; Sirnivas, S. Bottom Fixed Platform Dynamics Models Assessing Surface Ice Interactions for Transitional Depth Structures in the Great Lakes: FAST8 – IceDyn. Technical report, Golden Field Office, Golden, CO (United States), 2015. [CrossRef]

- Song, Z.; Hu, Y.; Cheng, Y.; Wang, H. Dynamic Ice Load Alleviation of Offshore Wind Turbine via Optimized Pitch Control. 2019 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC). IEEE, 2019, pp. 1–5. [CrossRef]

- Johnson, N.; Jonkman, J.; Wright, A.; Hayman, G.; Robertson, A. Verification of Floating Offshore Wind Linearization Functionality in OpenFAST. Journal of Physics: Conference Series 2019, 1356, 012022. [Google Scholar] [CrossRef]

- Arramounet, V.; de Winter, C.; Maljaars, N.; Girardin, S.; Robic, H. Development of coupling module between BHawC aeroelastic software and OrcaFlex for coupled dynamic analysis of floating wind turbines. Journal of Physics: Conference Series 2019, 1356, 012007. [Google Scholar] [CrossRef]

- Masciola, M.; Robertson, A.; Jonkman, J.; Coulling, A.; Goupee, A. Assessment of the Importance of Mooring Dynamics on the Global Response of the DeepCwind Floating Semisubmersible Offshore Wind Turbine. Twenty-third International Offshore and Polar Engineering Conference;, 2013.

- Tran, T.T.; Kim, D.H. The coupled dynamic response computation for a semi-submersible platform of floating offshore wind turbine. Journal of Wind Engineering and Industrial Aerodynamics 2015, 147, 104–119. [Google Scholar] [CrossRef]

- Masciola, M.; Robertson, A.; Jonkman, J.; Driscoll, F. Investigation of a FAST-OrcaFlex Coupling Module for Integrating Turbine and Mooring Dynamics of Offshore Floating Wind Turbines: Preprint. 2011 International Conference on Offshore Wind Energy and Ocean Energy;, 2011.

- Ross, A. Orcina Project 1405 Wind Turbine Validation Report. Technical report, Orcina Ltd., 2018.

- Azcona, J.; Munduate, X.; González, L.; Nygaard, T.A. Experimental validation of a dynamic mooring lines code with tension and motion measurements of a submerged chain. Ocean Engineering 2017, 129, 415–427. [Google Scholar] [CrossRef]

- Azcona, J.; Palacio, D.; Munduate, X.; González, L.; Nygaard, T.A. Impact of mooring lines dynamics on the fatigue and ultimate loads of three offshore floating wind turbines computed with IEC 61400-3 guideline. Wind Energy 2017, 20, 797–813. [Google Scholar] [CrossRef]

- Jonkman, J.M. Dynamics modeling and loads analysis of an offshore floating wind turbine. Technical Report November, 2007.

- Nygaard, T.A.; De Vaal, J.; Pierella, F.; Oggiano, L.; Stenbro, R. Development, Verification and Validation of 3DFloat; Aero-servo-hydro-elastic Computations of Offshore Structures. Energy Procedia 2016, 94, 425–433. [Google Scholar] [CrossRef]

- Armendariz, A.J.; Munduate, X.; Nygaard, T.A.; Hoyos, M.D. Development of OPASS Code for Dynamic Simulation Mooring Lines in Contact with Seabed. Technical report, 2011.

- Stewart, G.; Lackner, Matthew Robertson, A.; Jonkman, J.; Goupee, A. Calibration and Validation of a FAST Floating Wind Turbine Model of the DeepCwind Scaled Tension-Leg Platform: Preprint. 22nd International Offshore and Polar Engineering Conference; , 2012.

- Robertson, A.; Jonkman, J.; Masciola, M.; Song, H.; Goupee, A.; Coulling, A.; Luan, C. Definition of the Semisubmersible Floating System for Phase II of OC4. Technical report, National Renewable Energy Laboratory (NREL), Golden, CO (United States), 2014. [CrossRef]

- GL Garrad, H. Bladed Theory Manual Version 4.0. Technical report, 2010.

- Craig, Jr., R. Coupling of substructures for dynamic analyses - An overview. 41st Structures, Structural Dynamics, and Materials Conference and Exhibit; American Institute of Aeronautics and Astronautics: Reston, Virigina, 2000. [Google Scholar] [CrossRef]

- Beardsell, A.; Collier, W.; Han, T. Effect of linear and non-linear blade modelling techniques on simulated fatigue and extreme loads using Bladed. Journal of Physics: Conference Series 2016, 753, 042002. [Google Scholar] [CrossRef]

- Collier, W.; Milian Sanz, J. Comparison of linear and non-linear blade model predictions in Bladed to measurement data from GE 6MW wind turbine. Journal of Physics: Conference Series 2016, 753, 082004. [Google Scholar] [CrossRef]

- Larsen, T.J.; Hansen, A.M. How 2 HAWC2, the user’s manual. Technical report, Risø National Laboratory, Technical University of Denmark, Roskilde, Denmark, 2007.

- Popko, W.; Vorpahl, F.; Zuga, A.; Kohlmeier, M.; Jonkman, J.; Robertson, A.; Larsen, T.J.; Yde, A.; Sætertrø, K.; Okstad, K.M.; Nichols, J.; Nygaard, T.A.; Gao, Z.; Manolas, D.; Kim, K.; Yu, Q.; Shi, W.; Vásquez-Rojas, A.; Dubois, J.; Kaufer, D.; Thomassen, P.; de Ruiter, M.J.; Peeringa, J.M.; Huang, Z.; von Waaden, H. Offshore Code Comparison Collaboration Continuation (OC4), Phase 1 - Results of Coupled Simulations of an Offshore Wind Turbine With Jacket Support Structure, 2012.

- Bellew, S.; Yde, A.; Verelst, D.R. Application of the Aero-Hydro-Elastic Model, HAWC2-WAMIT, to Offshore Data from Floating Power Plants Hybrid Wind- and Wave-Energy Test Platform, P37. Proceedings of the 5th International Conference on Ocean Energy (ICOE); Marine Renewables Canada: Halifax, Nova scotia, Canada, 2014.

- Pavese, C.; Wang, Q.; Kim, T.; Jonkman, J.; Sprague, M.A. HAWC2 and BeamDyn: Comparison Between Beam Structural Models for Aero-Servo-Elastic Frameworks. European Wind Energy Association Annual Conference and Exhibition 2015 (EWEA 2015);, 2015.

- Gueydon, S.; Lindenburg, K.; Savenije, F. Coupling of Two Tools for the Simulation of Floating Wind Turbines. Volume 8: Ocean Renewable Energy. American Society of Mechanical Engineers, 2013. [CrossRef]

- Naciri, M.; Waals, O.; de Wilde, J. Time Domain Simulations of Side-by-Side Moored Vessels: Lessons Learnt From a Benchmark Test. Volume 1: Offshore Technology; Special Symposium on Ocean Measurements and Their Influence on Design. ASMEDC, 2007, pp. 801–811. [CrossRef]

- de Wilde, J.; van Dijk, A.; van den Berg, J.; Dekker, J. Direct Time Domain Downtime Assessment For LNG Operations Using Computer Cluster. Nineteenth International Offshore and Polar Engineering Conference;, 2009.

- Serraris, J.J. Time Domain Analysis for DP Simulations. Volume 1: Offshore Technology. ASMEDC, 2009, pp. 595–605. [CrossRef]

- Gueydon, S.; Weller, S. Study of a Floating Foundation for Wind Turbines. Journal of Offshore Mechanics and Arctic Engineering 2013, 135. [Google Scholar] [CrossRef]

- Gueydon, S.; Wei, Xu. Floating wind turbine motion assessment. OCEANS’11 MTS/IEEE KONA. IEEE, 2011, pp. 1–10. [CrossRef]

- Lindenburg, C. Comparison of Phatas Versions and the Wind turbine Module. Technical report, Netherlands, 2011.

- Lindenburg, C. PHATAS Release NOV-2003 and APR-2005 user’s manual: program for horizontal axis wind turbine analysis and simulation. Technical report, 2005.

- Huijs, F.; de Bruijn, R.; Savenije, F. Concept Design Verification of a Semi-submersible Floating Wind Turbine Using Coupled Simulations. Energy Procedia 2014, 53, 2–12. [Google Scholar] [CrossRef]

- Liu, Y.; Li, S.; Yi, Q.; Chen, D. Developments in semi-submersible floating foundations supporting wind turbines: A comprehensive review. Renewable and Sustainable Energy Reviews 2016, 60, 433–449. [Google Scholar] [CrossRef]

- Myhr, A.; Nygaard, T.A. Comparison of Experimental Results and Computations for Tension-Leg-Buoy Offshore Wind Turbines. Journal of Ocean and Wind Energy 2015, 2, 12–20. [Google Scholar]

- Azcona, J.; Bouchotrouch, F.; González, M.; Garciandía, J.; Munduate, X.; Kelberlau, F.; Nygaard, T.A. Aerodynamic Thrust Modelling in Wave Tank Tests of Offshore Floating Wind Turbines Using a Ducted Fan. Journal of Physics: Conference Series 2014, 524, 012089. [Google Scholar] [CrossRef]

- Pai, P. Highly Flexible Structures: Modeling, Computation, and Experimentation; American Institute of Aeronautics and Astronautics: Reston, VA, 2007. [Google Scholar] [CrossRef]

- Chaplin, J.R. Developments of stream-function wave theory. Coastal Engineering 1979, 3, 179–205. [Google Scholar] [CrossRef]

- Lee, C.H. WAMIT Theory Manual 1995.

- Babarit, A.; Delhommeau, G. Theoretical and numerical aspects of the open source BEM solver NEMOH. 11th European Wave and Tidal Energy Conference (EWTEC2015) 2015. [Google Scholar]

- Det Norske Veritaswadam. SESAM User Manual Developed and Marketed. Technical report, DNV, Norway, 2010.

- Le Cunff, C.; Heurtier, J.M.; Piriou, L.; Berhault, C.; Perdrizet, T.; Teixeira, D.; Ferrer, G.; Gilloteaux, J.C. Fully Coupled Floating Wind Turbine Simulator Based on Nonlinear Finite Element Method: Part I — Methodology. Volume 8: Ocean Renewable Energy. American Society of Mechanical Engineers, 2013. [CrossRef]

- Perdrizet, T.; Gilloteaux, J.C.; Teixeira, D.; Ferrer, G.; Piriou, L.; Cadiou, D.; Heurtier, J.M.; Le Cunff, C. Fully Coupled Floating Wind Turbine Simulator Based on Nonlinear Finite Element Method: Part II — Validation Results. Volume 8: Ocean Renewable Energy. American Society of Mechanical Engineers, 2013. [CrossRef]

- Leroy, J.M.; Poirette, Y.; Brusselle Dupend, N.; Caleyron, F. Assessing Mechanical Stresses in Dynamic Power Cables for Floating Offshore Wind Farms. Volume 10: Ocean Renewable Energy. American Society of Mechanical Engineers, 2017. [CrossRef]

- Ledru, R.; Le Cunff, C.; Heurtier, J.M.; Perdrizet, T.; Poirette, Y. Influence of Hydrodynamic Modeling Assumptions on Floating Wind Turbine Behaviour. Volume 9B: Ocean Renewable Energy. American Society of Mechanical Engineers, 2014. [CrossRef]

- Evren, S.; Unel, M.; Adak, O.K.; Erbatur, K.; Aksit, M.F. Modeling and simulation of a horizontal axis Wind Turbine using S4WT. 2012 International Conference on Renewable Energy Research and Applications (ICRERA). IEEE, 2012, pp. 1–6.

- Advanced aeroservoelastic modeling for horizontal axis wind turbines. Proceedings of the 9th International Conference on Structural Dynamics, EURODYN 2014, 2014, pp. 3097–3104.

- Gözcü, M.O.; Kayran, A. Investigation of the effect of bending twisting coupling on the loads in wind turbines with superelement blade definition. Journal of physics: conference series. IOP Publishing, 2014, Vol. 524, p. 12040.

- Heege, A.; Gaull, A.; Horcas, S.G.; Bonnet, P.; Defourny, M. Experiences in controller adaptations of floating wind turbines through advanced numerical simulation. AWEA WINDPOWER 2013 conference and exhibition, Chicago, 2013, pp. 5–8.

- Digital Solutions at DNV. Sesam Feature Description. Technical report, DNV, 2022.

- Alblas, L. Fixed Offshore Wind Structure Design, What Sesam can do for fixed offshore wind turbine structure design and analysis. Technical report, DNV GL – Digital Solutions, 2018.

- Barrera, C.; Guanche, R.; Rodríguez, Á.; Armesto, J.A.; Losada, I.J. On the importance of mooring system parametrisation for accurate floating structure designs. Marine Structures 2020, 72, 102765. [Google Scholar] [CrossRef]

- Lu, H.; Fan, T.; Zhou, L.; Chen, C.; Yu, G.; Li, X.; Hou, F. A rapid response calculation method for symmetrical floating structures based on state–space model solving in hybrid time-Laplace domain. Ocean Engineering 2020, 203, 107227. [Google Scholar] [CrossRef]

- Suzuki, H.; Shibata, H.; Fujioka, H.; Hirabayashi, S.; Ishii, K.; Kikuchi, H. Development of an Analysis Code of Rotor-Floater Coupled Response of a Floating Offshore Wind Turbine. Volume 8: Ocean Renewable Energy. American Society of Mechanical Engineers, 2013. [CrossRef]

- Ishii, K.; Suzuki, H.; Hirabayashi, S. 2015S-OS1-7 Improvement of Accuracy of Wave Drift Force of a Floating Offshore Wind Turbine. Conference Proceedings The Japan Society of Naval Architects and Ocean Engineers 20. The Japan Society of Naval Architects and Ocean Engineers, 2015, pp. 25–28.

- Shiohara, H.; Gonçalves, R.T.; Houtani, H.; Suzuki, H.; Schnepf, A.; Hirabayashi, S.; Carmo, L.H.S.; Nihei, Y. Numerical and experimental comparison of the wave response of a very light floating offshore wind turbine with guy wires. International Conference on Offshore Mechanics and Arctic Engineering. American Society of Mechanical Engineers, 2020, Vol. 84317, p. V001T01A055.

- Suzuki, H.; Xiong, J.; do Carmo, L.H.S.; Vieira, D.P.; de Mello, P.C.; Malta, E.B.; Simos, A.N.; Hirabayashi, S.; Gonçalves, R.T. Elastic response of a light-weight floating support structure of FOWT with guywire supported tower. Journal of Marine Science and Technology 2019, 24, 1015–1028. [Google Scholar] [CrossRef]

- Hooft, J.P. Hydrodynamic aspects of semi-submersible platforms 1972.

- Faraggiana, E.; Giorgi, G.; Sirigu, M.; Ghigo, A.; Bracco, G.; Mattiazzo, G. A review of numerical modelling and optimisation of the floating support structure for offshore wind turbines. Journal of Ocean Engineering and Marine Energy 2022, 8, 433–456. [Google Scholar] [CrossRef]

- Gözcü, O.; Kontos, S.; Bredmose, H. Dynamics of two floating wind turbines with shared anchor and mooring lines. Journal of Physics: Conference Series 2022, 2265, 042026. [Google Scholar] [CrossRef]

- Karimirad, M. Modeling aspects of a floating wind turbine for coupled wave–wind-induced dynamic analyses. Renewable Energy 2013, 53, 299–305. [Google Scholar] [CrossRef]

- Veldman, P.N. Essentials in Coupled Dynamics of Floating Offshore Wind Turbines. Master thesis, Delft University of Technology, 2020.

- Vriends, C. Efficient Long Term CFD Simulation of the Tri-Floater Using ComFLOW. Master thesis, Delft University of Technology, 2021.

- Duarte, T.; Tomas, D.; Matha, D.; Sarmento, A.; Schuon, F. Verification of Engineering Modeling Tools for Floating Offshore Wind Turbines. Volume 8: Ocean Renewable Energy. American Society of Mechanical Engineers, 2013. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).