Submitted:

29 May 2024

Posted:

30 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

Problem Statement

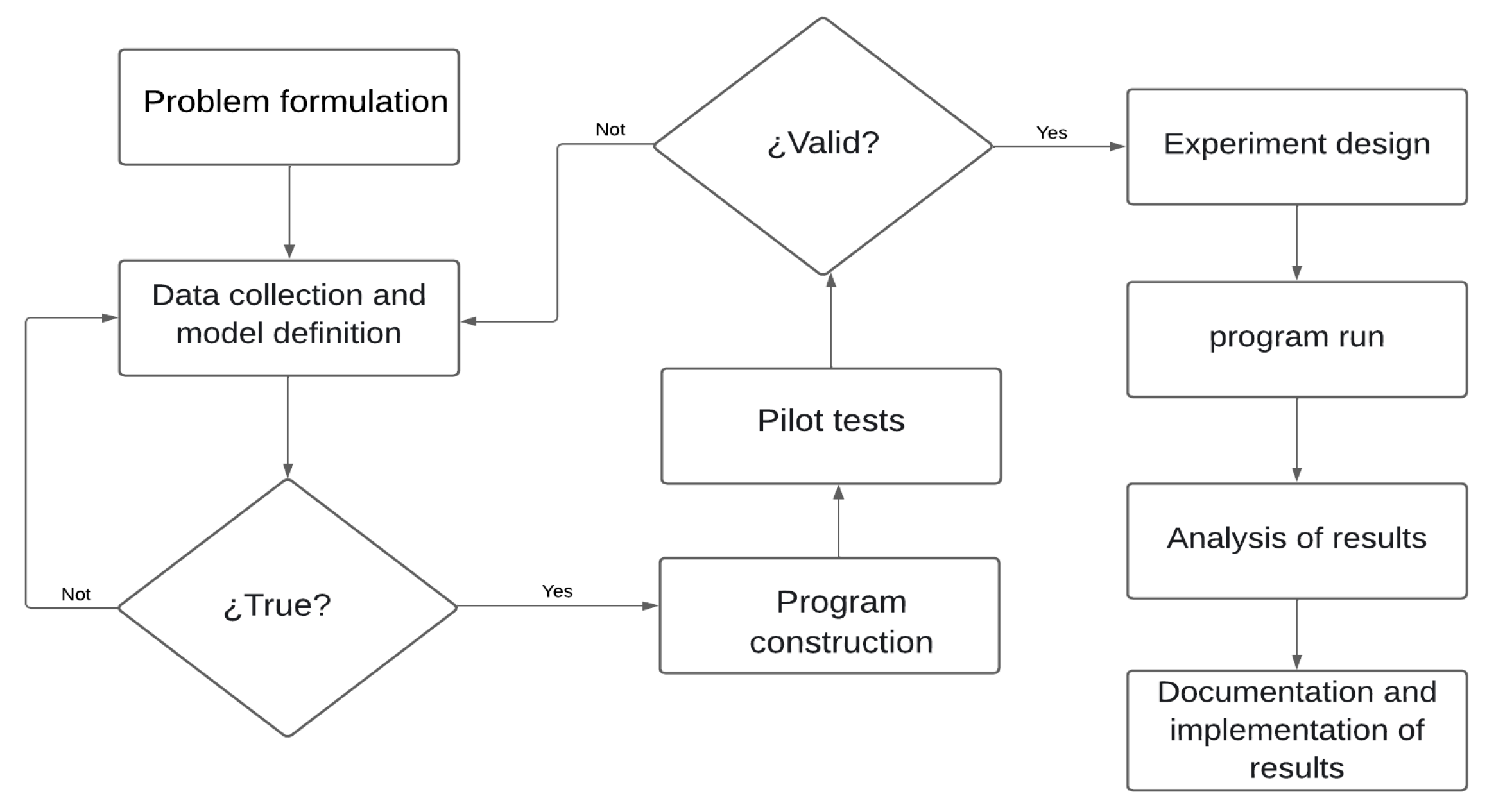

2. Materials and Methods

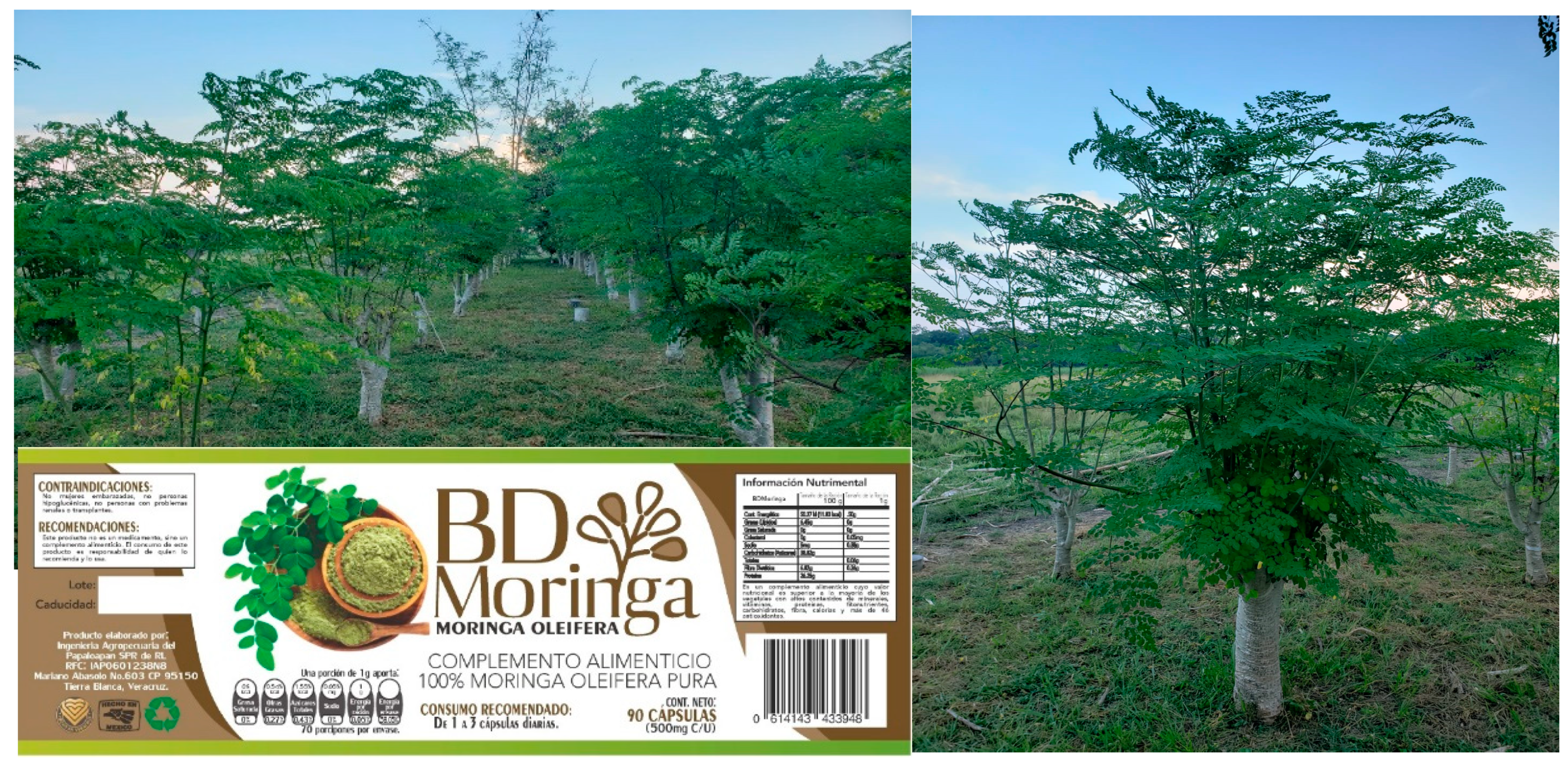

2.1. Study Site

2.2. Stage 1: Analysis of the Current Situation of the Study Area.

Identification of Study Variables:

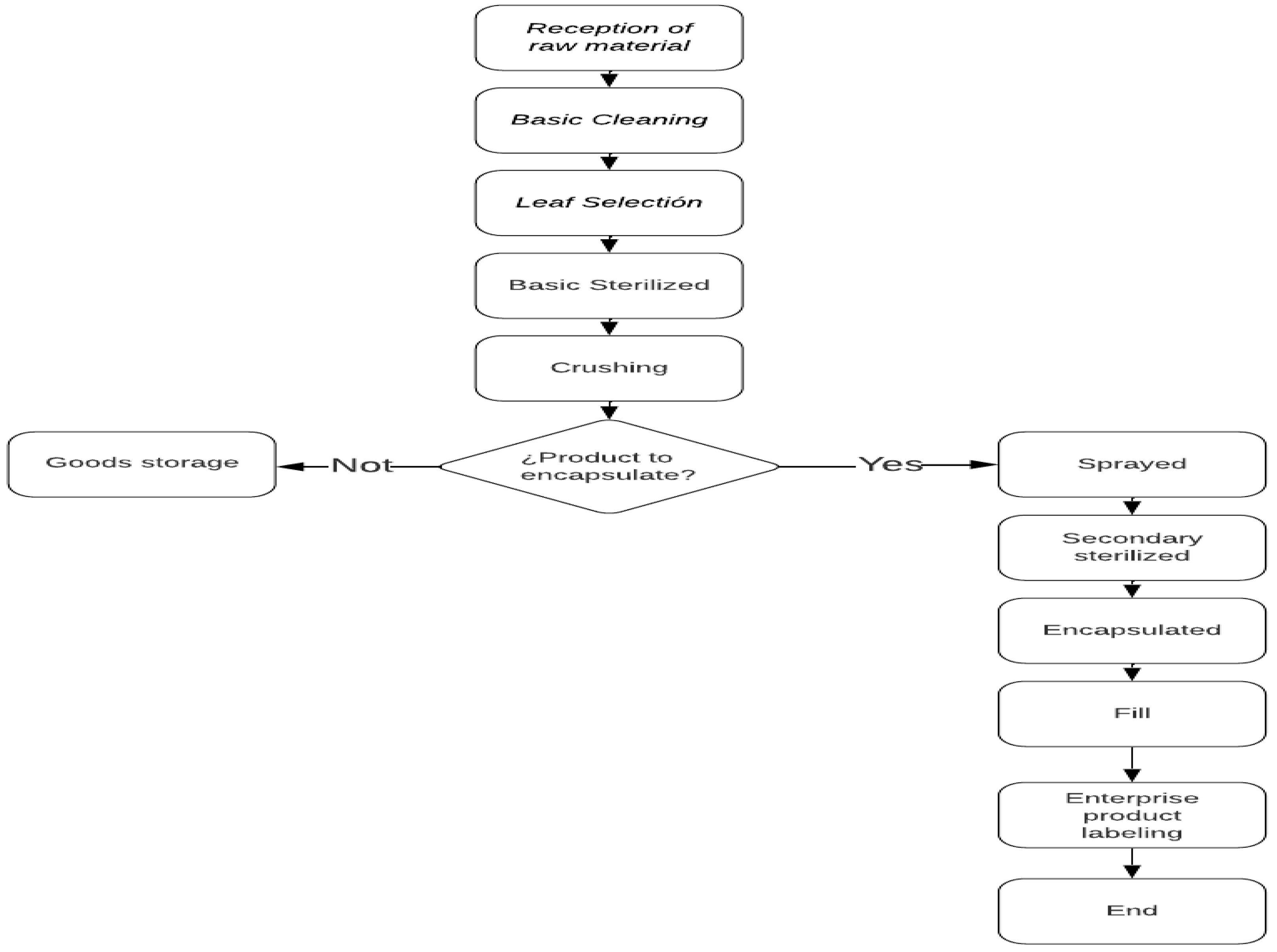

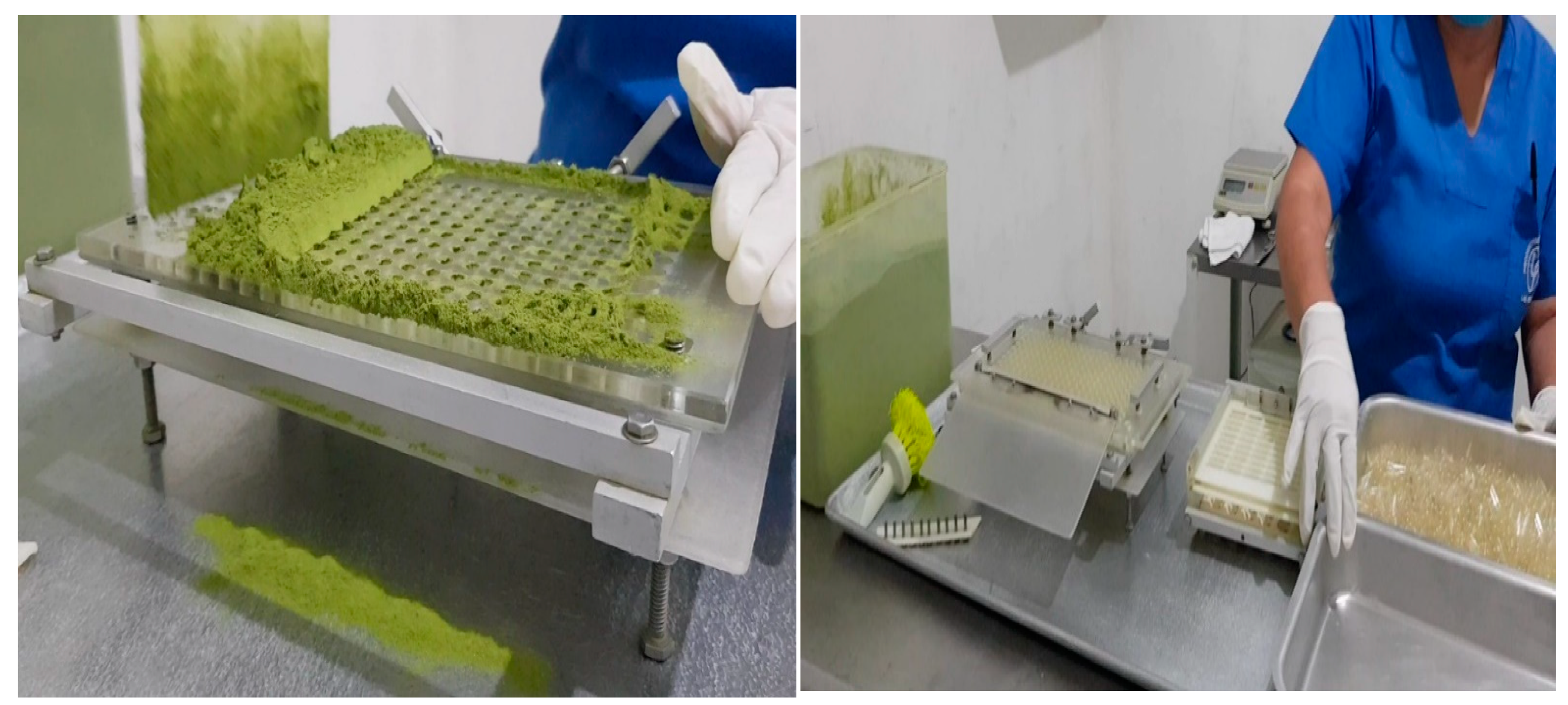

2.3. Stage 2: Analysis of the Key Process, Encapsulation

Data Sampling:

2.4. Stage 3: Analyzed Simulation Scenarios

Economic Evaluation: Economic and Financial Indicators

3. Results and Discussion

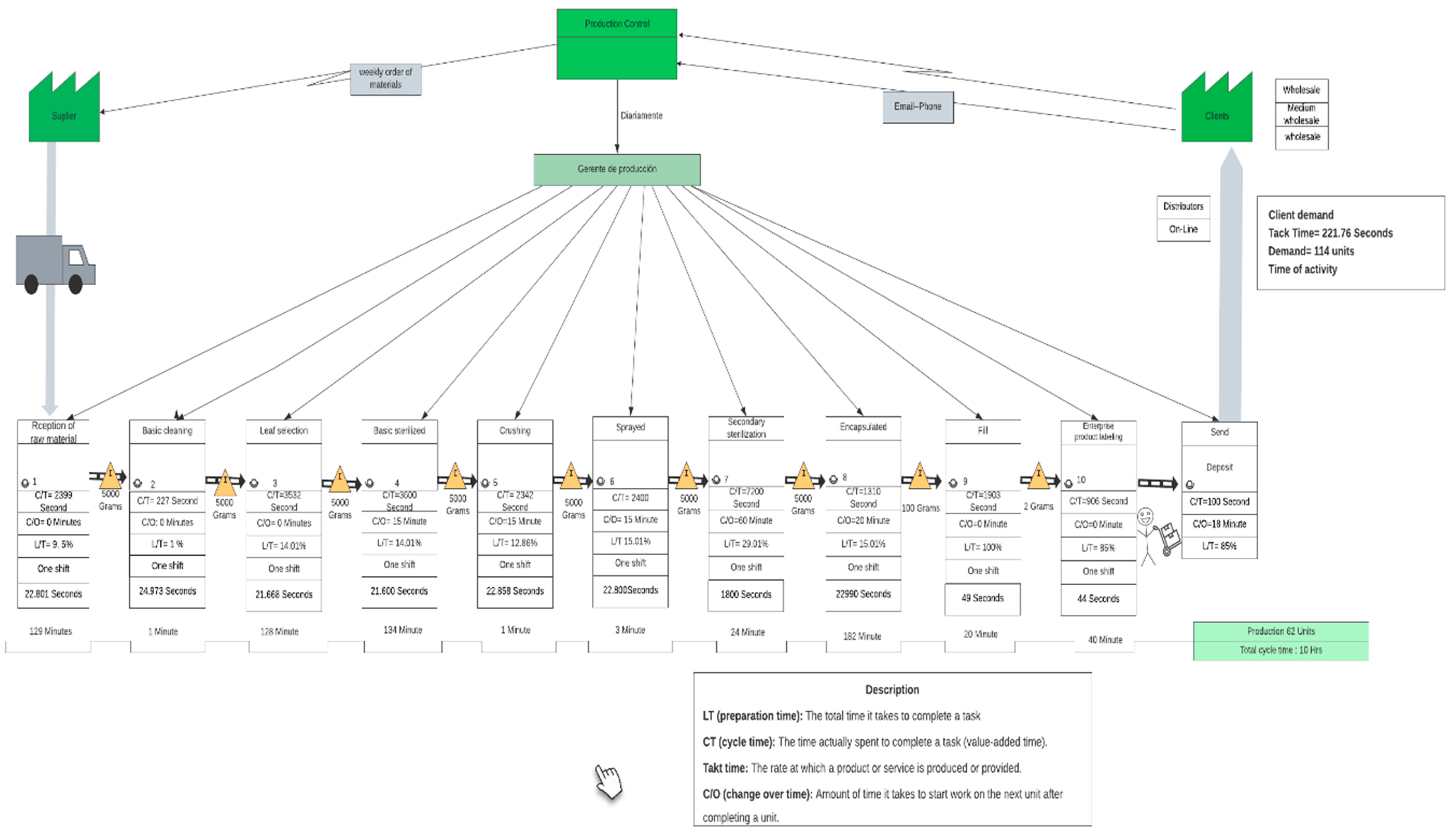

3.1. Process Characterization

3.2. Analysis of Study Variables in VSM:

3.3. Analysis of the Key Process, Encapsulation.

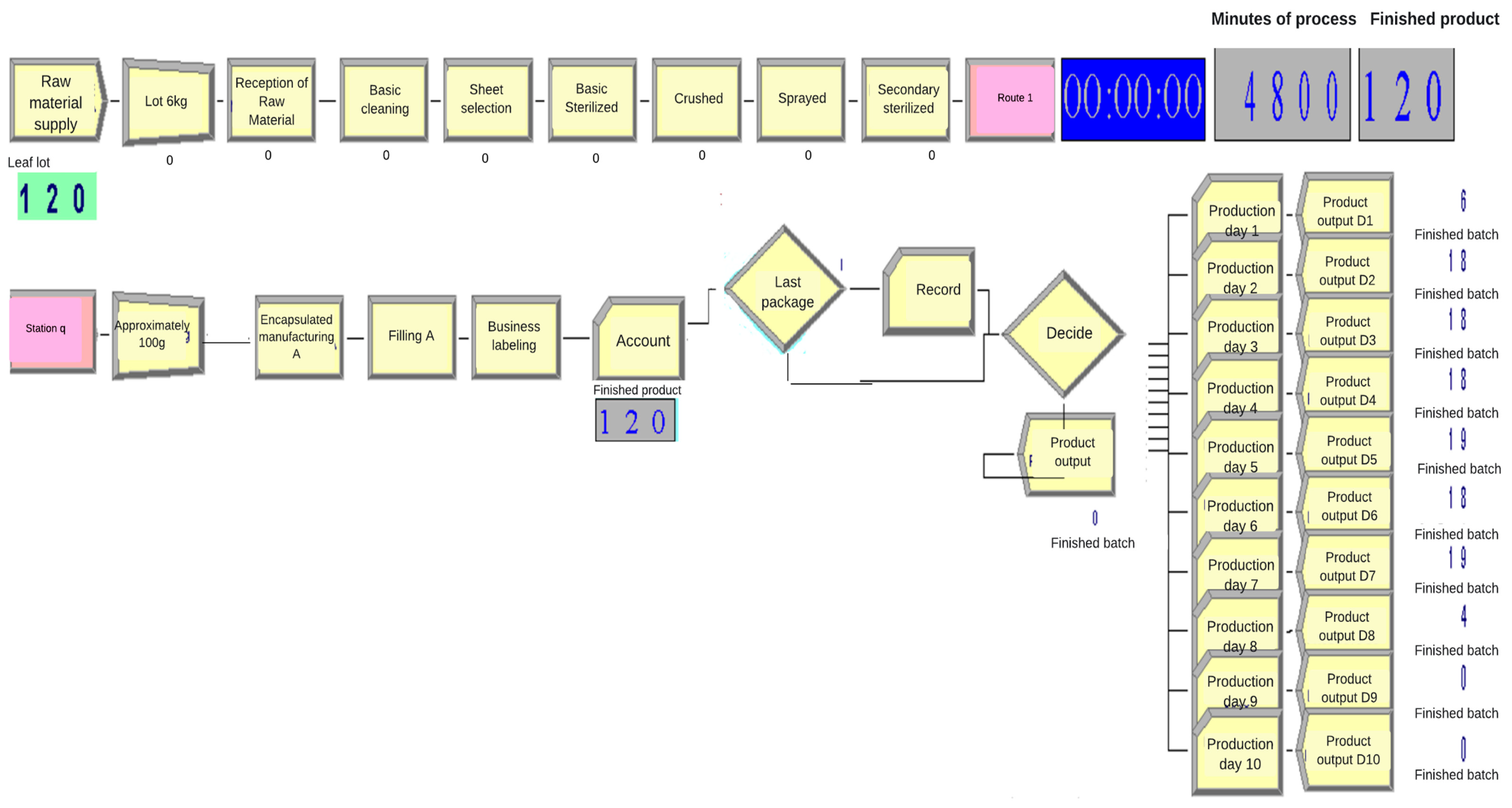

3.4. Simulation Model Description:

3.5. Determination of the Type of Distribution to Which the Data Fit:

3.6. Model Validation

3.7. Number of Replications:

3.8. Analyzed Simulation Scenarios.

3.9. Moringa Oleifera Capsule Production Costs and Financial Evaluation.

3.10. Potential Application of the Work.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Future Lines of Research

References

- Rockwell Automation Inc. Arena Simul. Softw. 2017,, 4. https://www.rockwellautomation.com/es-mx/products/software/arena-simulation/case-studies/hospital-simulation-prevents-unnecessary-investment.html.

- Roungas, B.; Bekius, F.; Verbraeck, A.; Meijer, S. Improving the decision-making qualities of gaming simulations. J. Simul. 2021, 1–14. [Google Scholar] [CrossRef]

- Black, L.; Tarquin, A. Economic engineering- 7 ed., 7a ed.; Mc Graw Hill: Mexico, 2012. [Google Scholar]

- Troncoso-Palacio, A.; Neira-Rodado, D.; Ortíz-Barrios, M.; Jiménez-Delgado, G.; Hernández-Palma, H. Using Discrete-Event-Simulation for Improving Operational Efficiency in Laboratories: A Case Study in Pharmaceutical Industry. En Lecture Notes in Computer Science; Springer International Publishing: Cham, 2018; pp. 440–451. [Google Scholar] [CrossRef]

- Reyes Mejia, R.; Troncoso Mendoza, B.; Troncoso Palacio, A. Discrete Event Simulation Applying Lean methodologies: Case study. Wooden Sector. Int. J. Manag. Sci. Oper. Res. 2020, 4, 440–451. [Google Scholar] [CrossRef]

- Robinson, S. Simulation: The Practice of Model Development and Use; Red Globe Press, 2020.

- Frough, O.; Khetwal, A.; Rostami, J. Predicting TBM utilization factor using discrete event simulation models. Tunn. Undergr. Space Technol. 2019, 87, 91–99. [Google Scholar] [CrossRef]

- Tavasszy, L. A. Predicting the effects of logistics innovations on freight systems: Directions for research. Transp. Policy 2020, 86, A1–A6. [Google Scholar] [CrossRef]

- Mendoza-Salguero, E.; De-La-Asunción-González, A.; Mejía-Vega, I.; Triana-Infante, J.; Troncoso Palacio, A. Análisis de Restricciones a través del Software Arena. Caso Empresa de Fabricación de Calzado. Boletin Innovacion. Logist. Oper. 2022, 4. [Google Scholar] [CrossRef]

- Cuzcano Espino, L. A.; Vasquez Mamani, A. S.; Ramos Bonifaz, J. V.; Bazan-Aguilar, A. Design of SMARTER multi-criteria model to improve the productivity of the Order-picking process: computational simulation. En 21st LACCEI International Multi-Conference for Engineering, Education and Technology (LACCEI 2023): “Leadership in Education and Innovation in Engineering in the Framework of Global Transformations: Integration and Alliances for Integral Development”; Latin American and Caribbean Consortium of Engineering Institutions, 2023. [CrossRef]

- Troncoso-Palacio, A.; Neira-Rodado, D.; Ortíz-Barrios, M.; Jiménez-Delgado, G.; Hernández-Palma, H. Using Discrete-Event-Simulation for Improving Operational Efficiency in Laboratories: A Case Study in Pharmaceutical Industry. En Lecture Notes in Computer Science; Springer International Publishing: Cham, 2018; pp. 440–451. [Google Scholar] [CrossRef]

- Johnstone, M.; Creighton, D.; Nahavandi, S. Simulation-based baggage handling system merge analysis. Simul. Model. Pract. Theory 2015, 53, 45–59. [Google Scholar] [CrossRef]

- Huang, P. B.; Yu, T.-Y.; Chou, Y.-j.; Lin, Y.-C. Simulation method for dispatching national border security manpower to mitigate manpower shortage. J. Air Transp. Manag. 2016, 57, 43–51. [Google Scholar] [CrossRef]

- Wong, T. C.; Xu, M.; Chin, K. S. A two-stage heuristic approach for nurse scheduling problem: A case study in an emergency department. Comput. & Oper. Res. 2014, 51, 99–110. [Google Scholar] [CrossRef]

- Valls, V.; Pérez, Á.; Quintanilla, S. Skilled workforce scheduling in Service Centres. Eur. J. Oper. Res. 2009, 193, 791–804. [Google Scholar] [CrossRef]

- Huang, P. B.; Yu, T.-Y.; Chou, Y.-j.; Lin, Y.-C. Simulation method for dispatching national border security manpower to mitigate manpower shortage. J. Air Transp. Manag. 2016, 57, 43–51. [Google Scholar] [CrossRef]

- Bolkovska, A.; Petuhova, J. Simulation-based Public Transport Multi-modal Hub Analysis and Planning. Procedia Comput. Sci. 2017, 104, 530–538. [Google Scholar] [CrossRef]

- Coronado-Hernández, J. R.; Ibáñez, S. F. U.; Gatica, G.; Rodríguez, M. A. Simulation Model of the Effect of the COVID-19 Biosecurity Protocol in the Queues for the Return to Face-to-Face Classes. Procedia Comput. Sci. 2023, 220, 904–908. [Google Scholar] [CrossRef] [PubMed]

- Navarro, M. Simulation of a manual order picking system in a convenience store chain distribution center,”. Proc. LACCEI Int. Multi-conference, 2020. http://ndltd.ncl.edu.tw/handle/47300620219584190941(accedido el 16/05/2024).

- Ibrahim, M. F.; Putri, M. M.; Sari, D. N.; Utama, D. M. Industrial area weighbridge simulation model considering vehicle capacity and destination using arena software. En 1st, International conference on technology, informatics, and engineering, Malang, Indonesia; AIP Publishing, 2022. [CrossRef]

- Pierreval, H.; Bruniaux, R.; Caux, C. A continuous simulation approach for supply chains in the automotive industry. Simul. Model. Pract. Theory 2007, 15, 185–198. [Google Scholar] [CrossRef]

- Vidalakis, C.; Tookey, J. E.; Sommerville, J. Logistics simulation modelling across construction supply chains. Constr. Innov. 2011, 11, 212–228. [Google Scholar] [CrossRef]

- Jaoua, A.; Riopel, D.; Gamache, M. A simulation framework for real-time fleet management in internal transport systems. Simul. Model. Pract. Theory 2012, 21, 78–90. [Google Scholar] [CrossRef]

- Motraghi, A.; Marinov, M. V. Analysis of urban freight by rail using event based simulation. Simul. Model. Pract. Theory 2012, 25, 73–89. [Google Scholar] [CrossRef]

- Köhler, J.; Brauer, C. Transformation in freight transport: New analysis requirements and potential modelling approaches. Transp. Res. Procedia 2023, 72, 4420–4427. [Google Scholar] [CrossRef]

- Wu, W.; Shen, L.; Ji, X. (.; Jin, W. Analysis of freeway service patrol with discrete event-based simulation. Simul. Model. Pract. Theory 2014, 47, 141–151. [CrossRef]

- Kamrani, M.; Hashemi Esmaeil Abadi, S. M.; Rahimpour Golroudbary, S. Traffic simulation of two adjacent unsignalized T-junctions during rush hours using Arena software. Simul. Model. Pract. Theory 2014, 49, 167–179. [Google Scholar] [CrossRef]

- Fumasoli, T.; Bruckmann, D.; Weidmann, U. Operation of freight railways in densely used mixed traffic networks – An impact model to quantify changes in freight train characteristics. Res. Transp. Econ. 2015, 54, 15–19. [Google Scholar] [CrossRef]

- Arathi, H. S.; Smith, T. J. Drought and temperature stresses impact pollen production and autonomous selfing in a California wildflower, Collinsia heterophylla. Ecol. Evol. 2023, 13. [Google Scholar] [CrossRef]

- Saval-R, A. Remolque autopropulsado para transporte de embarcaciones. Maestria, Escola Tècnica Superior d’Enginyeria Industrial de Barcelona, Barcelona, 2020.

- Mora-G, L. A. Transportation logistics and cargo distribution, 23a ed.; Ecoe Ediciones:Bogota, 2023.

- Sun, L.; Tirachini, A.; Axhausen, K. W.; Erath, A.; Lee, D.-H. Models of bus boarding and alighting dynamics. Transp. Res. 2014, 69, 447–460. [Google Scholar] [CrossRef]

- Leich, G.; Bischoff, J. Should autonomous shared taxis replace buses? A simulation study. Transp. Res. Procedia 2019, 41, 450–460. [Google Scholar] [CrossRef]

- Mepparambath, R. M.; Soh, Y. S.; Jayaraman, V.; Tan, H. E.; Ramli, M. A. A novel modelling approach of integrated taxi and transit mode and route choice using city-scale emerging mobility data. Transp. Res. 2023, 170, 103615. [Google Scholar] [CrossRef]

- Delcea, C.; Chirita, N. Exploring the Applications of Agent-Based Modeling in Transportation. Appl. Sci. 2023, 13, 9815. [Google Scholar] [CrossRef]

- Bae, J. W.; Lee, C.-H.; Lee, J.-W.; Choi, S. H. A data-driven agent-based simulation of the public bicycle-sharing system in Sejong city. Simul. Model. Pract. Theory 2024, 130, 102861. [Google Scholar] [CrossRef]

- Gittins, P.; McElwee, G.; Tipi, N. Discrete event simulation in livestock management. J. Rural Stud. 2020, 78, 387–398. [Google Scholar] [CrossRef]

- Rockwell Automation Inc. Arena Simul. Softw. 2014,, 4. https://www.rockwellautomation.com/es-mx/products/software/arena-simulation/case-studies/hospital-simulation-prevents-unnecessary-investment.html (accedido el 17/05/2024).

- Johnstone, M.; Creighton, D.; Nahavandi, S. Simulation-based baggage handling system merge analysis. Simul. Model. Pract. Theory 2008, 53, 45–59. [Google Scholar] [CrossRef]

- Cabrera, V. E.; Hildebrand, P. E.; Jones, J. W.; Letson, D.; de Vries, A. An integrated North Florida dairy farm model to reduce environmental impacts under seasonal climate variability. Agric., Ecosyst. & Environ. 2006, 113, 82–97. [Google Scholar] [CrossRef]

- Del Prado, A.; Misselbrook, T.; Chadwick, D.; Hopkins, A.; Dewhurst, R. J.; Davison, P.; Butler, A.; Schröder, J.; Scholefield, D. SIMSDAIRY: A modelling framework to identify sustainable dairy farms in the UK. Framework description and test for organic systems and N fertiliser optimisation. Sci. Total Environ. 2011, 409, 3993–4009. [Google Scholar] [CrossRef]

- Jones, J. W.; Antle, J. M.; Basso, B.; Boote, K. J.; Conant, R. T.; Foster, I.; Godfray, H. C. J.; Herrero, M.; Howitt, R. E.; Janssen, S.; et al. Brief history of agricultural systems modeling. Agric. Syst. 2017, 155, 240–254. [Google Scholar] [CrossRef]

- Herrero, M.; Havlik, P.; Valin, H.; Notenbaert, A.; Rufino, M. C.; Thornton, P. K.; Blummel, M.; Weiss, F.; Grace, D.; Obersteiner, M. Biomass use, production, feed efficiencies, and greenhouse gas emissions from global livestock systems. Proc. National Acad. Sci. 2013, 110, 20888–20893. [Google Scholar] [CrossRef]

- Herrero, M.; González-Estrada, E.; Thornton, P. K.; Quirós, C.; Waithaka, M. M.; Ruiz, R.; Hoogenboom, G. IMPACT: Generic household-level databases and diagnostics tools for integrated crop-livestock systems analysis. Agric. Syst. 1996, 92, 240–265. [Google Scholar] [CrossRef]

- Rufino, M. C.; Herrero, M.; Van Wijk, M. T.; Hemerik, L.; De Ridder, N.; Giller, K. E. Lifetime productivity of dairy cows in smallholder farming systems of the Central highlands of Kenya. Animal 2009, 3, 1044–1056. [Google Scholar] [CrossRef]

- Ruiz, R.; Tedeschi, L. O.; Marini, J. C.; Fox, D. G.; Pell, A. N.; Jarvis, G.; Russell, J. B. The Effect of a Ruminal Nitrogen (N) Deficiency in Dairy Cows: Evaluation of the Cornell Net Carbohydrate and Protein System Ruminal N Deficiency Adjustment. J. Dairy Sci. 2002, 85, 2986–2999. [Google Scholar] [CrossRef]

- Moore, A. D.; Donnelly, J. R.; Freer, M. GRAZPLAN: Decision support systems for Australian grazing enterprises. III. Pasture growth and soil moisture submodels, and the GrassGro DSS. Agric. Syst. 1997, 55, 535–582. [Google Scholar] [CrossRef]

- Gerber, P.; Uwizeye, A.; Schulte, R.; Opio, C.; de Boer, I. Nutrient use efficiency: a valuable approach to benchmark the sustainability of nutrient use in global livestock production? Curr. Opin. Environ. Sustain. 2014, 9-10, 122–130. [Google Scholar] [CrossRef]

- Van Wijk, M. T.; Rufino, M. C.; Enahoro, D.; Parsons, D.; Silvestri, S.; Valdivia, R. O.; Herrero, M. Farm household models to analyse food security in a changing climate: A review. Glob. Food Secur. 2007, 3, 77–84. [Google Scholar] [CrossRef]

- Vayssières, J.; Guerrin, F.; Paillat, J.-M.; Lecomte, P. GAMEDE: A global activity model for evaluating the sustainability of dairy enterprises Part I – Whole-farm dynamic model. Agric. Syst. 2009, 101, 128–138. [Google Scholar] [CrossRef]

- Lisson, S.; MacLeod, N.; McDonald, C.; Corfield, J.; Pengelly, B.; Wirajaswadi, L.; Rahman, R.; Bahar, S.; Padjung, R.; Razak, N.; et al. A participatory, farming systems approach to improving Bali cattle production in the smallholder crop–livestock systems of Eastern Indonesia. Agric. Syst. 2010, 103, 486–497. [Google Scholar] [CrossRef]

- Rodriguez, D.; Cox, H.; deVoil, P.; Power, B. A participatory whole farm modelling approach to understand impacts and increase preparedness to climate change in Australia. Agric. Syst. 2014, 126, 50–61. [Google Scholar] [CrossRef]

- Van Wijk, M. T.; Tittonell, P.; Rufino, M. C.; Herrero, M.; Pacini, C.; Ridder, N. d.; Giller, K. E. Identifying key entry-points for strategic management of smallholder farming systems in sub-Saharan Africa using the dynamic farm-scale simulation model Nuances-farmsim. Agric. Syst. 2009, 102, 89–101. [Google Scholar] [CrossRef]

- Tensi, A. F.; Ang, F.; van der Fels-Klerx, H. J. Microbial Applications and Agricultural Sustainability: A Simulation Analysis of Dutch Potato Farms. SSRN Electron. J. 2023. [CrossRef]

- Goo, J.; Kwak, Y.; Kim, J.; Kang, J.; Shin, H.; Jo, S.-K.; Huh, J.-H. Development of early design tool for aquaculture buildings using building performance simulation: A case study of an indoor fish farm. Dev. Built Environ. 2024, 100363. [Google Scholar] [CrossRef]

- Konapathri, R.; Azimov, U. Assessment of ammonia distribution in a livestock farm using CFD simulations. Smart Agric. Technol. 2024, 100376. [Google Scholar] [CrossRef]

- Kongnuan, S.; Thongjub, N. A 3D-numerical simulation of groundwater flow and salinity in a rice field adjacent to a marine shrimp farm. Environ. Adv. 2024, 15, 100473. [Google Scholar] [CrossRef]

- Kelton, W. D.; Zupick, N.; Ivey, N. Simulation with Arena (McGraw-Hill Series in Industrial Engineering and Management); McGraw-Hill Higher Education, 2024.

- Gittins, P.; McElwee, G.; Tipi, N. Discrete event simulation in livestock management. J. Rural Stud. 2020, 78, 387–398. [Google Scholar] [CrossRef]

- Fibigr, J.; Šatínský, D.; Solich, P. Current trends in the analysis and quality control of food supplements based on plant extracts. Anal. Chim. Acta 2018, 1036, 1–15. [Google Scholar] [CrossRef]

- Mota-Fernández, I. F.; Valdés-Rodríguez, O. A.; Quintas, G. S. Socioeconomic characteristics and agricultural practices of Moringa Oleifera lam Producers. In México. AgroProductivity 2019, 12. [CrossRef]

- Delfin-Portela, E.; Carrión-Delgado, J. M.; Garcia-SANTAMARIA, L. E. Characterization of moringa oleifera production systems in the state Veracruz. At The IV National Forum for the Evaluation of the Female Gender 2019, 1–12. [Google Scholar]

- Mathur B. Trees for life. En Conference, 4 de may of 2012; ACM Press, 2005.

- Gopalakrishnan, L.; Doriya, K.; Kumar, D. S. Moringa oleifera: A review on nutritive importance and its medicinal application. Food Sci. Hum. Wellness 2016, 5, 49–56. [Google Scholar] [CrossRef]

- Dhakad, A. K.; Ikram, M.; Sharma, S.; Khan, S.; Pandey, V. V.; Singh, A. Biological, nutritional, and therapeutic significance of Moringa oleifera Lam. Phytotherapy Res. 2019, 33, 2870–2903. [Google Scholar] [CrossRef]

- Thapa, K.; Poudel, M.; Adhikari, P. Moringa oleifera: A Review Article on Nutritional Properties and its Prospect in the Context of Nepal. Acta Sci. Agric. 2019, 3, 47–54. [Google Scholar] [CrossRef]

- Dhiman, J. A Review on Medicinal uses of Moringa oleifera. J. Drug Deliv. Ther. 2023, 13, 197–201. [Google Scholar] [CrossRef]

- Carrión, J. M.; Valdés Rodríguez, O. A.; Gallardo López, F.; Palacios Wassenaar, O. M. Agroecological potential of Moringa oleifera Lam. For The State Of Veracruz. Rev. Mex. Science. 2022, 13. [Google Scholar] [CrossRef]

- Fahey, J. Fahey, J. W. (2005). Moringa oleifera: a review of the medical evidence for its nutritional, therapeutic, and prophylactic properties. Part 1. Trees for life Journal,2005 1, 1-15.

- Babu, R.; Chaudhuri, M. Home water treatment by direct filtration with natural coagulant. J. Water Health 2005, 3, 27–30. [Google Scholar] [CrossRef] [PubMed]

- Khawaja T, M.; Tahira, M.; UI, I. Moringa oleifera: a natural gift-A review. J. Pharm. Sci. Res. 2010, 2–11. [Google Scholar]

- Bazán C, J. C.; Reyes S, V. A. Effects of moringa of Hypertensive adults. Cent Health San pedro (Bachelor's Thesis, Lib.) 2018.

- Famakinwa, A.; Oguntibejo, O.; Jideani, V. Fortification of Foodstuffs (Food Material) with Moringa oleifera. Fortification of Foodstuffs (Food Material) With Moringa Oleifera. International, 2024; pp 1–64. [CrossRef]

- Su, X.; Lu, G.; Ye, L.; Shi, R.; Zhu, M.; Yu, X.; Li, Z.; Jia, X.; Feng, L. Moringa oleifera Lam.: a comprehensive review on active components, health benefits and application. RSC Adv. 2023, 13, 24353–24384. [Google Scholar] [CrossRef] [PubMed]

- Servicio de Información Agroalimentaria y Pesquera - SIAP, El poder de la moringa en la salud, s. f. (Mexico). Diario Oficial de la Federación, March 1, 2023. https://www.gob.mx/siap/articulos/el-poder-de-la-moringa-en-la-salud?idiom=es#:~:text=Some%20benefits%20of%20the%20consumption%20of%20of%20of%20of,Control%20levels%20of%20cholesterol.

- Mota-Fernández, I. F.; Valdés-Rodríguez, O. A.; Quintas, G. S. Socioeconomic characteristics and agricultural practices of producers OF Moringa oleifera LAM. AgroProductividad 2019, 12. [Google Scholar] [CrossRef]

- Delfín-Portela, E.; Carrión-Delgado, J. M.; Garcia-SANTAMARIA, L. E. Characterization of moringa oleifera production systems in the state of Veracruz. In IV Foro Nacional para la Evaluación del Desarrollo del Género Femenino 2019. IV Foro Nac. Para El Desarro. For Gen. Fem. 2019,, 1-12.

- Carrión, J. M.; Valdés Rodríguez, O. A.; Gallardo López, F.; Palacios Wassenaar, O. M. Agroecological potential of Moringa oleifera Lam. for the state of Veracruz. Rev. Mex. Sci. For. 2022, 13. [Google Scholar] [CrossRef]

- Olson, M. E.; Alvarado-Cárdenas, L. O. Where to grow the miracle tree, Moringa oleifera, in Mexico? An analysis of its potential distribution. Rev. Mex. Biodivers. 2016, 87, 1089–1102, [80,73] Famakinwa, A.; Oguntibejo, O.; Jideani, V. Fortification of Foodstuffs (Food Material) with Moringa oleifera. Fortification of Foodstuffs (Food Material) With Moringa Oleifera. International, 2024; pp 1-64. DOI: 10.9734/bpi/mono/978-81-969800-2-3. [Google Scholar] [CrossRef]

- Fibigr, J.; Šatínský, D.; Solich, P. Current trends in the analysis and quality control of food supplements based on plant extracts. Anal. Chim. Acta 2018, 1036, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Dhiman, J. A Review on Medicinal uses of Moringa oleifera. J. Drug Deliv. Ther. 2023, 13, 197–201. [Google Scholar] [CrossRef]

- Su, X.; Lu, G.; Ye, L.; Shi, R.; Zhu, M.; Yu, X.; Li, Z.; Jia, X.; Feng, L. Moringa oleifera Lam.: a comprehensive review on active components, health benefits and application. RSC Adv. 2023, 13, 24353–24384. [Google Scholar] [CrossRef] [PubMed]

- Makkar, H. P. S.; Becker, K. Nutrional value and antinutritional components of whole and ethanol extracted Moringa oleifera leaves. Anim. Feed Sci. Technol. 1996, 63, 211–228. [Google Scholar] [CrossRef]

- Castro, M. The moringa tree (Moringa oleifera Lam.): a renewable alternative for the development of the economic and environmental sectors of Colombia. Repos.unimilitar Colomb. 2013, 18, 3. [Google Scholar]

- Gharsallah, K.; Rezig, L.; Rajoka, M.; Mehwish, H.; Chew, S. Moringa oleifera: Processing, phytochemical composition and industrial application; South African Journal of Botany: Africa, 2023. [Google Scholar]

- Abridged version of The State of Food and Agriculture 2023; FAO, November 2023. [CrossRef]

- Fibigr, J.; Šatínský, D.; Solich, P. Current trends in the analysis and quality control of food supplements based on plant extracts. Anal. Chim. Acta 2018, 1036, 1–15. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). WHO Global Database on Child Growth and Malnutrition; World Health Organization: Geneva, 2021. [Google Scholar]

- Lafont Mendoza, J.; Negrete Humanez, W.; Espitia Arrieta, A. Estudios químicos realizados a la semilla de moringa oleifera lam y su impacto en la salud humana: una revisión teórica. In Science and Technology for Environmental, Cultural and Socioeconomic Development; Artemis Publishing House, 2021; pp 159-170. [CrossRef]

- Calendario-M, B.; Ruiz Rosado, O.; Perez, P.; Martinez, A.; Vargas, L. Aplicación de modelos de simulación en el estudio y planificación de la agricultura, una revisión. Trop. Subtrop. Agroecosystems 2011, 14. [Google Scholar]

- Theisen, M. F.; Flores, K. N.; Balhorn, L. S.; Schweidtmann, A. M. Digitization of chemical process flow diagrams using deep convolutional neural networks. Digit. Chem. Eng. 2022, 100072. [Google Scholar] [CrossRef]

- Horsthofer-Rauch, J.; Schumann, M.; Milde, M.; Vernim, S.; Reinhart, G. Digitalized value stream mapping: review and outlook. Procedia CIRP 2022, 112, 244–249. [Google Scholar] [CrossRef]

- Hawarneh, A. A.; Bendak, S.; Ghanim, F. Construction site layout planning problem: Past, present and future. Expert Syst. With Appl. 2020, 114247. [Google Scholar] [CrossRef]

- Baca-Urbina, G. Project evaluation - 7. edition; McGraw-Hill Interamericana: Mexico, 2016. [Google Scholar]

- Slack, N.; Jones, A. Operations & Process Management: Principles & Practice for Strategic Impact; Pearson Education, 2021.

- Hernández-Sampieri, R.; Fernández-Collado, C.; Baptista, L. P. Analysis of quantitative data. Research methodology; Mc Graw Hill: Mexico, 2020. [Google Scholar]

- Law, A. M. Simulation modeling and analysis, 15a ed.; McGraw-Hill: Estados Unidos de América, 2014. [Google Scholar]

- Law, A. M. Simulation modeling and analysis Student Edition, 15a ed.; McGraw-Hill: Estados Unidos de América, 2024. [Google Scholar]

- Rodríguez Balza, M. Y.; Machado Torrealba, W. S.; Villamarin Oliveros, A. J. Sampling for quality control in the manufacturing process of metallic food containers. Research Eng. Tecnol. 2019, 20, 1–9. [Google Scholar] [CrossRef]

- Guillen-R, A.; Buela-C, G. Psychometric update and differential item functioning in the State Trait Anxiety Inventory (STAI). Psicothema 2011, 23, 510–515. [Google Scholar]

- Villamarin O, A. Sampling for quality control in the manufacturing process of metallic food containers. Research Eng. Tecnol. 2015, 20, 1–9. [Google Scholar]

- Besterfield, D. H. Quality control, 8th ed.; Pearson: Mexico City, 1998. [Google Scholar]

- Woodall, W. H.; Montgomery, D. C. Some Current Directions in the Theory and Application of Statistical Process Monitoring. J. Qual. Technol. 2014, 46, 78–94. [Google Scholar] [CrossRef]

- Goedhart, R.; Schoonhoven, M.; Does, R. J. M. M. On guaranteed in-control performance for the Shewhart X and control charts. J. Qual. Technol. 2018, 50, 130–132. [Google Scholar] [CrossRef]

- Saleh, N. A.; Mahmoud, M. A.; Keefe, M. J.; Woodall, W. H. The Difficulty in Designing ShewhartX̄andXControl Charts with Estimated Parameters. J. Qual. Technol. 2015, 47, 127–138. [Google Scholar] [CrossRef]

- Zhou, M. Variable sample size and variable sampling interval Shewhart control chart with estimated parameters. Oper. Res. 2017, 17, 17–37. [Google Scholar] [CrossRef]

- Romero-Saldaña, M. Goodness-of-fit tests to normal distribution. Enfermeria Del Trab. 2016, 6, 144, [103,6] Robinson, S. Simulation: The Practice of Model Development and Use; Red Globe Press, 2020. [Google Scholar] [CrossRef]

- Robinson, S. (2005). Discrete-event simulation: from the pioneers to the present, what next? Journal of the Operational Research Society, 56, 619–629. [CrossRef]

- Black, L.; Tarquin, A. Engineering economics - 7 ed., 7th ed; Mc Graw Hill: Mexico, 2012. [Google Scholar]

- Ortiz, C. A. Kaizen Assembly: Designing, Constructing, and Managing a Lean Assembly Line; Taylor & Francis Group, 2006.

- Cedillo-Portillo, J., Ponce-González, A., J. González-Coronel, V., Vega-Sánchez, M., Teresa Zayas-Pérez, M., & Soriano-Moro, G. (2024). Utilización de moringa oleífera como un coagulante-floculante natural para la descontaminación de agua. RD-ICUAP, 10, 224–235. [CrossRef]

- De la Cruz-Uribe, A., Jesús-Castañeda, M. Á., Bolívar-Fuentes, R. C., Laines-Canepa, J. R., & Hernández-Barajas, J. R. (2023). Análisis beneficio-costo de techos verdes extensivos en condiciones del trópico húmedo en Villahermosa, México. Ecosistemas y Recursos Agropecuarios, 10. [CrossRef]

- Delgado Tello, P. Modelos de Simulación para la Evaluación de Proyectos de Inversión. Neumann Bus. Rev. 2019, 5, 97–107. [Google Scholar] [CrossRef]

| Sampling Technique: Random Sampling Instrument: Time Recording Table | |||

| Type of instrument | Time Sheet | Target Population | Units produced in the production process |

| Study Representativeness | Local | Sample Frame | Number of daily lots, 24 hours |

| Number of Sampling Points | 10 | Sampling method Unit Selection | Systematic |

| Number of Data per Point | 50 | Data Collection Method | Digital Stopwatch |

| Total Number of Samples | 50 | Dates of Data Collection | Phase1 March (2022) Phase 2 April (2022) |

| Sampling Design, Measurement Instrument, Capture, and Analysis. | E.D.-P., E.A.B.-T.,R.A.M-A, J.M.C.-D., M.J.H-R., M.E.G.-R and O.B.-S | Confidence Level % | 95% |

| Operativo de campo, supervisión | E.D-P | Margen de error % | 5% |

| Process Stage | Measures of Central Tendency (minutes) | Test Statistic | Data Distribution Fit | Theoretical distribution statistics. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kolmogorov-Smirnov | Anderson-Darling | |||||||||||

| s | Statistic KS | Alpha | P | Statistic AD | 1-α | P | Minimum value | µ | σ | |||

| Raw Material Reception | 39.99 | 3.663 | .116 | .005 | .477 | 1.3 | .005 | .232 | Log normal | 30 | 2.25 | .395 |

| Basic Cleaning | 3.78 | .310 | .137 | .005 | .275 | 1.99 | .005 | .934 | Log normal | 3 | -.320 | .496 |

| Leaf Selection | 58.87 | .583 | .131 | .005 | .329 | 1.51 | .005 | .174 | Uniform | 58.02 | ||

| Primary Sterilization | 4.79 | .116 | .125 | .005 | .382 | .73 | .005 | .534 | Log normal | 4.49 | -2.23 | 0.14 |

| Crushing | 39.02 | 2.66 | .158 | .005 | 0.145 | 2.18 | .005 | .073 | Log normal | 33.895 | 1.66 | .582 |

| Pulverization | 40.00 | 3.94 | .175 | .005 | .008 | 2.25 | .005 | .004 | Log normal | 30 | 2.23 | 0.51 |

| Secondary Sterilization | 120.12 | .142 | .102 | .005 | .635 | .427 | .005 | .821 | Log normal | 119.81 | .0097 | .129 |

| Encapsulation | 21.84 | 1.55 | .00973 | .005 | .694 | .418 | .005 | .831 | Log normal | 19.49 | .907 | .540 |

| Business Labeling | 4.51 | .570 | .168 | .005 | .106 | 1.44 | .005 | .192 | Log normal | 3.45 | .329 | .441 |

| Real | Simulated | |||

|---|---|---|---|---|

| Runs | Xj | Yj | Zj=Xj - Yj | |

| 1 | 3,465.66 | 3,469 | -3.34 | 76.38 |

| 2 | 3,490 | 3,467.97 | 22.03 | 276.55 |

| 3 | 3,485.22 | 3,439.94 | 45.28 | 1,590.41 |

| 4 | 3,460.81 | 3,448.79 | 12.02 | 43.82 |

| 5 | 3,440.12 | 3,434.99 | 5.13 | 0.07 |

| 6 | 3,450.23 | 3,450.19 | 0.04 | 28.72 |

| 7 | 3,445.30 | 3,476.31 | -31.01 | 1,325.68 |

| 8 | 3,463.12 | 3,470.78 | -7.66 | 170.56 |

| 9 | 3,459.15 | 3,461.51 | -2.36 | 60.21 |

| 10 | 3,449.51 | 3,448.08 | 1.43 | 15.76 |

| 11 | 3,455.28 | 3,456.14 | -0.86 | 39.18 |

| 12 | 3,482.27 | 3,444.58 | 37.69 | 1,042.64 |

| 13 | 3,443.08 | 3,444.25 | -1.17 | 43.16 |

| 14 | 3,462 | 3,465.90 | -3.9 | 86.49 |

| 15 | 3,463.23 | 3,455.42 | 7.81 | 5.8 |

| Total | 81.13 | 4,805.43 | ||

| Average | 5.4 | |||

| Replications or runs | Average manufacturing time (min) |

|---|---|

| 1 | 3,469 |

| 2 | 3,467.97 |

| 3 | 3,439.94 |

| 4 | 3,448.79 |

| 5 | 3,434.99 |

| 6 | 3,450.19 |

| 7 | 3,476.31 |

| 8 | 3,470.78 |

| 9 | 3,461.51 |

| 10 | 3,448.08 |

| 11 | 3,456.14 |

| 12 | 3,444.58 |

| 13 | 3,444.25 |

| 14 | 3,465.9 |

| 15 | 3,455.42 |

| Average | 3,455.59 |

| Standard Deviation | 12.4949 |

| Simulation Scenario | Total Time | Encapsulation | Personnel Occupied | Worked Hours | Worked Days | Time Reduction (%) | Downtime (Hours) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Minutes | Hours | Working Days | Capsules | Batches | Kg | ||||||

| 1E200C | 3,455 | 57.5 | 7 | 24,000 | 120 | 12 | 1 | 56 | 7 | 35 | 0 |

| 2E200C | 2,263 | 37.7 | 4 | 24,000 | 120 | 12 | 2 | 32 | 4 | 24 | 24 |

| 1E800C | 1,415 | 23.5 | 2 | 24,000 | 120 | 12 | 1 | 16 | 2 | 60 | 35 |

| Simulation Scenario | Total Process Time | Limit o Simulation Model Due to Raw Material Limitation per Week | Larger Queue in System | Personnel | Labor Cost (USD) |

Days Occupied per Week | Production Cost per Bottle (USD) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Minutes | Hours | Working Days | Capsules | Batches | Kg | ||||||

| 1E200C | 3,455 | 57.5 | 7 | 24,000 | 120 | 12 | Encapsulation | 1 | 830.51 | 7 | 3.93 |

| 2E200C | 2,263 | 37.7 | 4 | 24,000 | 120 | 12 | Encapsulation | 2 | 474.58 | 4 | 3.64 |

| 1E800C | 1,415 | 23.5 | 2 | 24,000 | 120 | 12 | Encapsulation | 1 | 237.29 | 2 | 3.45 |

| Costs | Unit of Measure | Unit Cost | Quantity | Year 1 |

|---|---|---|---|---|

| Raw Material Reception | ||||

| Disinfection | Month | 148.31 | 12.00 | 1,779.66 |

| II. Processing | ||||

| Labor | Month | 0.18 | 12,000.00 | 8,542.37 |

| III. Indirect Costs | ||||

| Energy | Month | 332.20 | 12.00 | 3,986.44 |

| Water | Month | 24.32 | 12.00 | 291.86 |

| Telephony | Month | 71.19 | 12.00 | 854.24 |

| IV. Supplies | ||||

| Raw Material per month | Kgs | 1.42 | 1,200.00 | 20,501.68 |

| Packaging Material | Batch | 0.65 | 12,800.00 | 8,276.61 |

| Advertising | ||||

| Digital Media | Month | 711.86 | 1.00 | 711.86 |

| Transportation and Hauling | Freight | 0.059 | 12,000.00 | 711.86 |

| Distributable | Kgs | $0.45 | 12,000.00 | 316.78 |

| Total Costs | 45,973.36 | |||

| Production Cost per Bottle of 90 capsules | 3.59 | |||

| Gross Profit | 227,382.41 | |||

| Administrative Expenses | 593.22 | |||

| Fees | 88.98 | Month | 1,067.80 | |

| Stationery and Desk Supplies | 29.66 | Month | 29.66 | |

| Depreciation and Amortization | 3,707.63 | |||

| Total Costs and Expenses | 50,274.21 | |||

| Net Operating Income | 22,3081.57 | |||

| Final production cost per bottle of 90 capsules | 3.93 | |||

| Final production cost per capsule | 0.043 | |||

| Financial indicators | ||

| B/C ratio | 5.03 USD | |

| NPV | 922,370.11 USD | |

| IRR | 502.60% | 42.09% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).